EBCN

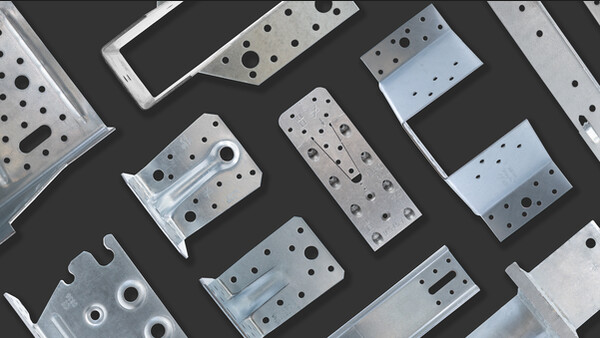

Angle bracket for cladding

The EBCN angle bracket has been designed to fix vertical battens directly to the supporting structure without the need for additional battens, it creates a zone for insulation and/or ventilation between the wall and the cladding.

Service class 2

galvanised steel Z450

Product Details

Features

Material

- Pre-galvanised mild steel. S250GD with Z450 coating (acc. to EN10346)

- 2.5 mm thickness

Benefits

- Connect vertical battens directly to the supporting structure.

- Creates a zone for insulation or ventilation.

- Reduces installation time, materials and cost.

- Suitable for cavities 50mm to 145mm.

- Get an oblong hole to adjust the plumb line of the batten/profile,

- The coating (Z450) allows to use it next to the seaside (200 m), suitable with atmosphere within 3 km from seaside (no direct contact by sea water )

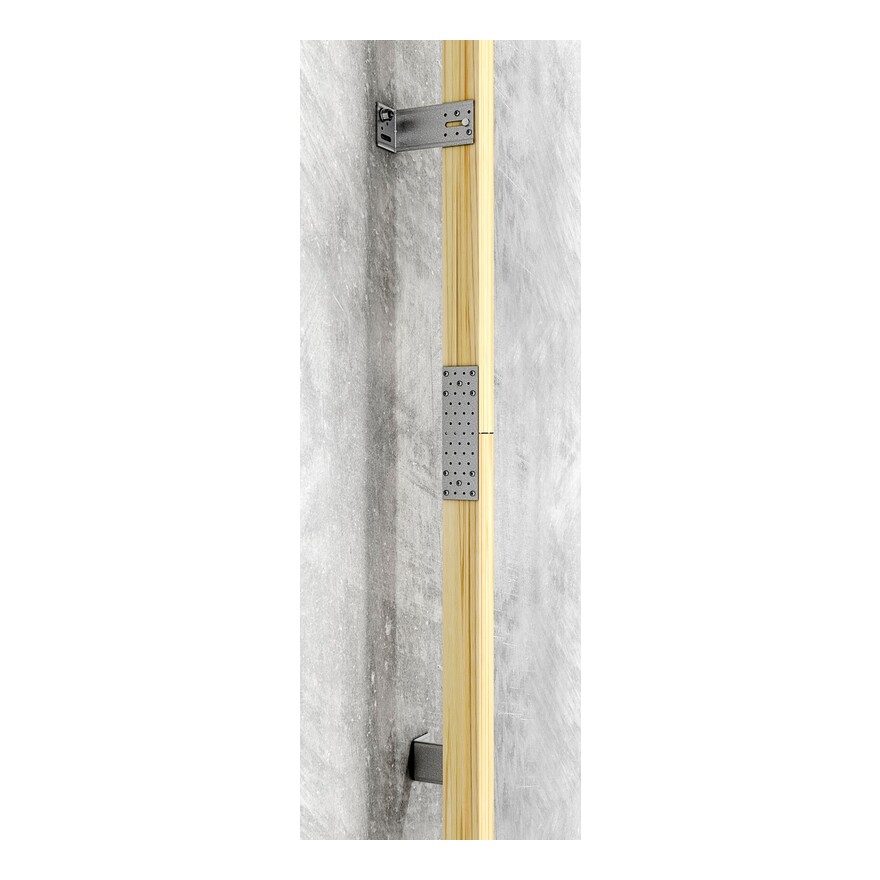

Application

Header member

- Supporting member: concrete, masonry, etc.

- Supported member: solid wood, etc.

For Use With

- Fastening of timber battens or steel profile, to support exterior cladding (ETICS).

Technical Data

Product dimensions

| References | DB nr. | Product dimensions [mm] | Holes flange A | Holes flange B | ||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | t | Ø6 | Dim. oblong holes | Ø9.0x20 [mm] | ||

| EBCN40/2.5 | - | 40 | 50 | 60 | 2.5 | 4 | 9.0x20 | 2 |

| EBCN50/2.5 | - | 50 | 50 | 60 | 2.5 | 4 | 9.0x30 | 2 |

| EBCN60/2.5 | - | 60 | 50 | 60 | 2.5 | 6 | 9.0x35.5 | 2 |

| EBCN70/2.5 | - | 70 | 50 | 60 | 2.5 | 6 | 9.0x51 | 2 |

| EBCN80/2.5 | - | 80 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN90/2.5 | - | 90 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN100/2.5 | 2408465 | 100 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN110/2.5 | 2408467 | 110 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN120/2.5 | 2408469 | 120 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN130/2.5 | 2408470 | 130 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN140/2.5 | 2408471 | 140 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN150/2.5 | 2408472 | 150 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN160/2.5 | 2408473 | 160 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN170/2.5 | 2408475 | 170 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN180/2.5 | 2408476 | 180 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN190/2.5 | 2408477 | 190 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN200/2.5 | 2408478 | 200 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN210/2.5 | 2408479 | 210 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN220/2.5 | 2408480 | 220 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN230/2.5 | 2408481 | 230 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN240/2.5 | 2408483 | 240 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN250/2.5 | 2408484 | 250 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

| EBCN260/2.5 | - | 260 | 50 | 60 | 2.5 | 8 | 9.0x51 | 2 |

Product characteristic capacities - Timber to concrete - 1 angle bracket per connection

| References | Product characteristic capacities - Timber to Concrete - 1 angle bracket per connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - 1 angle bracket per connection [kN] | ||||||||

| Flange A [kN] | Flange B | R1,k [kN] | R2,k [kN] | ||||||

| Qty | Type | Qty | Type | Qty | Type | 1 mm slip | 3 mm slip | ||

| EBCN40/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.93 | 0.93 | 2.3 |

| EBCN50/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.93 | 0.93 | 2.3 |

| EBCN60/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.93 | 0.93 | 2.3 |

| EBCN70/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.93 | 0.93 | 2.3 |

| EBCN80/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.87 | 0.87 | 2.3 |

| EBCN90/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.81 | 0.81 | 2.3 |

| EBCN100/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.75 | 0.75 | 2.3 |

| EBCN110/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.65 | 0.72 | 2.3 |

| EBCN120/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.54 | 0.69 | 2.3 |

| EBCN130/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.47 | 0.67 | 2.3 |

| EBCN140/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.44 | 0.63 | 2.3 |

| EBCN150/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.38 | 0.58 | 2.3 |

| EBCN160/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.35 | 0.55 | 2.3 |

| EBCN170/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.3 | 0.51 | 2.3 |

| EBCN180/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.26 | 0.48 | 2.3 |

| EBCN190/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.24 | 0.46 | 2.3 |

| EBCN200/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.2 | 0.42 | 2.3 |

| EBCN210/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.19 | 0.41 | 2.3 |

| EBCN220/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.17 | 0.38 | 2.3 |

| EBCN230/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.15 | 0.36 | 2.3 |

| EBCN240/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.14 | 0.33 | 2.3 |

| EBCN250/2.5 | 1 | Screw Ø8.0x40 | 2 | Screw Ø5.0x40 | 1 | Ø8 | 0.13 | 0.31 | 2.3 |

| EBCN260/2.5 | 2 | Screw Ø8.0x40 | 3 | Screw Ø5.0x40 | 1 | Ø8 | 0.11 | 0.26 | 2.3 |

Note - Slip under load measured at extremety of bracket

Installation

Installation

Fixing

Drill holes: Number and diameter, see table of dimensions.

- Wood rafters :

- 1 LAG lag screw dia. 8-50 + 2 screws anti-rotation 5 x 40 mm. (it can be either TTUFS, TTZNFS or SSH screws)

1 SSH Ø 8 x 40 mm + 2 screws anti-rotation Ø 5 x 40 mm.(it can be either TTUFS, TTZNFS or SSH screws)

- Concrete substrate : FM 753 evo M8 68/5 anchor or mechanical anchor FM-X5 8-80/10

- Hollow masonry substrate :FM-X5 8-80/10 nylon plug or chemical anchor: AT-HP or POLY-GP resin + LMAS M8-95/20 threaded rod + SH M16-130 screen.

Installation

- Draw the position of brackets, in a staggered manner on either side of the position of the batten/profile. Min 3 bracket per batten/profile. For batten/profile under 80cm: min 2 brackets. The spacing of brackets depends on bracket and anchor capacity, with a maximum of 1m when using "L" profiles or under seismic specifications, and with a maximum of 1.35m otherwhise. When brackets cannot be set in a staggered manner, then the maximum spacing is 0.8m. The ovehang of batten/profile shall not exceed 0.25m.

- Secure the bracket onto the support with the appropriate anchor, placed through the top oblong hole.

- Set the insulation layer

- Secure the batten/profile with one Ø8mm screw in the oblong hole, adjust the verticality of the batten/profile, then set 2 additionnal Ø5mm screw to block the position.

- install the cladding/facade with the appropriate fastener.