ETB

Concealed Beam Hanger

The ETB concealed connector comes in two parts. The first is pocketed in the header timber and fixed with nails, while the second part is fitted to the end of the beam with screws.

No slots or dowel holes are necessary, speeding up production.

Note: Order nails and screws separately.

CE Marking

ETA

Service class 2

Fire resistance R 30

Aluminium

Product Details

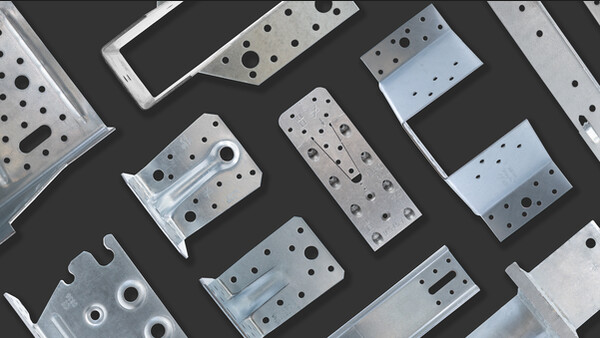

Images

Features

Material

- Joist plate: 10mm aluminium.

- Header plate: 6mm aluminium.

Benefits

- Concealed connection.

- Multiple applications.

Application

Header member

Glulam joist and headers.

For Use With

Wood to wood connections only.

Technical Data

Product Dimensions

| References | Joist Size [mm] | Product Dimensions [mm] | Header holes | Joist holes | Box Quantity | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Height | A | B | C | D | t1 | t2 | Ø5 | Ø5.4 | |||

| Min | Min | Max. | ||||||||||

| ETB90-B | 70 | 115 | 150 | 90 | 60 | 58 | 69 | 6 | 10 | 6 | 4 | 25 |

| ETB120-B | 70 | 150 | 200 | 121 | 60 | 85 | 95 | 6 | 10 | 9 | 6 | 25 |

| ETB160-B | 70 | 185 | 250 | 166 | 60 | 95 | 130 | 6 | 10 | 11 | 8 | 25 |

| ETB190-B | 90 | 220 | 300 | 195 | 75 | 138 | 165 | 6 | 10 | 19 | 11 | 25 |

| ETB230-B | 90 | 255 | 350 | 230 | 75 | 138 | 200 | 6 | 10 | 19 | 14 | 25 |

Wood/wood fastening- Characteristic values in kn

| References | Wood/wood fastening- Characteristic values in kn | |||

|---|---|---|---|---|

| Number of Fasteners | Characteristic Capacities - Timber C24 [kN] | |||

| Header | Joist | R1,k | ||

| Qty | Type | Qty | CSFT5,0x70 | |

| ETB90-B | 6 | CNA4,0x40 | 4 | 11.1 |

| ETB120-B | 9 | CNA4,0x40 | 6 | 16.7 |

| ETB160-B | 11 | CNA4,0x40 | 8 | 20.4 |

| ETB190-B | 19 | CNA4,0x40 | 11 | 29.7 |

| ETB230-B | 19 | CNA4,0x40 | 14 | 35.2 |

Product characteristic capacities - Timber beam to timber post

| References | Product characteristic capacities - Timber beam to timber post | |||

|---|---|---|---|---|

| Number of Fasteners | Product characteristic capacities - Timber C24 [kN] | |||

| Header | Joist | R1,k | ||

| Qty | Type | Qty | CSFT5,0x70 | |

| ETB90-B | 6 | CNA4,0x40 | 4 | 11.1 |

| ETB120-B | 9 | CNA4,0x40 | 6 | 16.7 |

| ETB160-B | 11 | CNA4,0x40 | 8 | 20.4 |

| ETB190-B | 12 | CNA4,0x40 | 9 | 22.2 |

| ETB230-B | 12 | CNA4,0x40 | 10 | 22.2 |

Installation

Installation

Fasteners

To achieve stated loads, nails and screws used must comply with the ETA-04/0013.

Installation

Installation of ETB is simplified by the use of a jig.

The pocket installation can be routed by using a Ø16 mm cutter with Ø30 mm washer.

CAUTION: ETB bracket should not be used for an assembly with a negative slope

Certification

Declaration of Performance (DoP)

uk-dop-e07-0245-issue-4.pdf

(97 KB)

uk-dop-e07-0245-issue-3.pdf

(67.19 KB)

uk-dop-e07-0245-issue-2.pdf

(34.18 KB)

uk-dop-e07-0245-issue-1.pdf

(32.07 KB)

European Technical Assessment (ETA)

eta-07-0245-2018-08-15.pdf

(2.68 MB)

eta070245-sst-je-ch-r5-2016-rev-a.pdf

(3.36 MB)