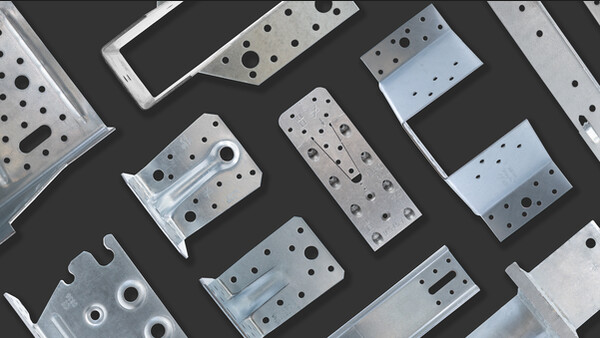

TUS

Concealed Beam Hanger

These concealed hangers ensure a completely invisible assembly. The slot in the head facilitates on-site installation. TUS, factory bent, are suitable for skewed applications.

CE Marking

ETA

Service class 2

Fire resistance R 30

Available in Connector Selector

Product Details

Features

Material

- Steel S250GD + Z275 according to NF EN 10346.

- Thickness 3 mm.

- Half-hour fire resistance subject to a special installation.

Benefits

Invisible assembly

Optimized implementation complies with Eurocodes

Application

Header member

- Supporting member: solid wood, glued-laminated wood, composite lumber.

- Supported member: solid wood, glued-laminated wood, composite lumber.

For Use With

- Joists.

- Purlins.

- Supporting beam.

Technical Data

Product Dimensions

| References | Joist Size [mm] | Header dimensions [mm] | Product Dimensions [mm] | Header holes | Joist holes | Box Quantity | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Height | Post width | A | B | C | t | α [°] | Ø5 | Ø8,5 | Ø12,5 | ||||||

| Min | Max. | Min β=0 | Min β≠0 | Max. | Min | Min | Max. | |||||||||

| TU/S12 | 60 | 120 | 120 | 160 | 200 | 68 | 96 | 97.5 | 40 | 3 | 30 | 85 | 6 | 4 | - | - |

| TU/S16 | 60 | 160 | 160 | 190 | 240 | 88 | 134 | 104.5 | 60 | 3 | 30 | 85 | 18 | - | 3 | - |

| TU/S20 | 60 | 160 | 200 | 225 | 280 | 88 | 174 | 104.5 | 60 | 3 | 30 | 85 | 22 | - | 4 | - |

| TU/S24 | 60 | 160 | 240 | 260 | 300 | 88 | 214 | 104.5 | 60 | 3 | 30 | 85 | 26 | - | 5 | - |

| TU/S28 | 60 | 160 | 280 | 295 | 340 | 88 | 254 | 104.5 | 60 | 3 | 30 | 85 | 30 | - | 6 | - |

Product characteristic capacities - Timber beam to timber beam - full nailing - with slope and skew α=60°

| References | Product characteristic capacities - Timber beam to timber beam - full nailing - with slope and skew α=60° | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Fasteners | Product characteristic capacities - Timber C24 [kN] | |||||||||||||||||||

| Header | Joist | R1,k - Slope β=0° | R1,k - Slope β=15° | R1,k - Slope β=30° | R1,k - Slope β=45° | |||||||||||||||

| Qty | Type | Qty | Type | Dowels length [mm] | Dowels length [mm] | Dowels length [mm] | Dowels length [mm] | |||||||||||||

| 60 | 80 | 100 | 120 | 60 | 80 | 100 | 120 | 60 | 80 | 100 | 120 | 60 | 80 | 100 | 120 | |||||

| TU/S12 | 6 | CSA5,0x40 | 4 | STD8 | 7.4 | 8.2 | 9.1 | 9.6 | 7.2 | 7.9 | 8.7 | 9.3 | 6.9 | 7.5 | 8.2 | 9 | 6.6 | 7.1 | 7.8 | 8.5 |

| TU/S16 | 18 | CSA5,0x40 | 3 | STD12 | 16.4 | 16.9 | 17.8 | 19 | 15.9 | 16.3 | 17.1 | 18.1 | 15.4 | 15.7 | 16.4 | 17.2 | 15 | 15.4 | 15.9 | 16.7 |

| TU/S20 | 22 | CSA5,0x40 | 4 | STD12 | 25 | 25.8 | 27.2 | 28.9 | 24.2 | 24.8 | 25.9 | 27.4 | 23.6 | 24 | 25 | 26.2 | 22.9 | 23.5 | 24.4 | 25.5 |

| TU/S24 | 26 | CSA5,0x40 | 5 | STD12 | 34.4 | 35.4 | 37.3 | 39.5 | 33.3 | 34.1 | 35.6 | 37.6 | 32.4 | 33.1 | 34.4 | 36.1 | 31.6 | 32.6 | 33.7 | 35.2 |

| TU/S28 | 30 | CSA5,0x40 | 6 | STD12 | 44.3 | 45.5 | 47.8 | 50.6 | 43 | 43.8 | 45.8 | 48.2 | 41.7 | 42.7 | 44.3 | 46.5 | 40.9 | 42.2 | 43.7 | 45.6 |

R2,k capacities can be calculated as R2,k = R1,k x (nb of dowels - 1) / (nb of dowels).

The top dowel is not considered for the uplift capacities as it is placed in an open hole.

Product characteristic capacities - Safe working loads - skewed connection

| References | Safe working loads - skewed connection | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Fasteners | Installation: skew = 0° to 60°, slope = 0° | Installation: skew = 0° to 60°, slope = 45° | ||||||||||

| Header | Joist | R1.SWL [kN] | R1.SWL [kN] | |||||||||

| Qty | Type | Qty | Type | Dowels length [mm] | Dowels length [mm] | |||||||

| 60 | 80 | 100 | 120 | 60 | 80 | 100 | 120 | |||||

| TU/S12 | 6 | CSA5,0x40 | 4 | STD8 | 2.5 | 2.5 | 2.5 | - | 2.3 | 2.5 | 2.5 | - |

| TU/S16 | 18 | CSA5,0x40 | 3 | STD12 | 3.4 | 4.8 | 6.1 | 6.1 | 3 | 4.1 | 5.3 | 5.3 |

| TU/S20 | 22 | CSA5,0x40 | 4 | STD12 | 5.5 | 7.7 | 9.8 | 9.8 | 4.8 | 6.7 | 8.5 | 8.5 |

| TU/S24 | 26 | CSA5,0x40 | 5 | STD12 | 8 | 11.1 | 13.3 | 13.3 | 6.9 | 9.6 | 12.3 | 12.3 |

| TU/S28 | 30 | CSA5,0x40 | 6 | STD12 | 10.7 | 14.9 | 16.3 | 16.3 | 9.3 | 12.9 | 16.3 | 16.3 |

The skew may be precise when ordering the products

Installation

Installation

Fixing

On supporting wood member: TUS

- CNA annular ring-shank nails dia. 4.0 x 50 mm or CSA screws dia. 5.0 x 40 mm.

On supported member: Steel dowel S235JR type STD12

- TUS12: dia. 8 mm type STD 8.

- TUS16 to 28: dia. 12 mm type STD 12.

The length of the dowels is less than or equal to the width of the supported joist.

TUS: wood/wood fastening only with nails/screws

Installation

- Make a vertical notch in the joist end (width 6mm for TUS12 and 9mm for TUS16 to TUS28),

- Mark the position of the dowels on the joist before drilling holes - diameter of the hole according to the diameter of the dowel

- Insert the top dowel in the joist

- Route a 6mm deep pocket in either the joist end or the header. This is not compulsory, it is used to improve the aesthetic of the connection

- Fix Install the joist onto the concealed beam hanger by hooking the joist onto the concealed beam hanger. Top dowel hooks into slotted top hole on the concealed beam hanger.

- Install reamining dowels.the concealed beam hanger to the header with nails or screws

Certification

European Technical Assessment (ETA)

eta-07-0245-2018-08-15.pdf

(2.68 MB)

eta070245-sst-je-ch-r5-2016-rev-a.pdf

(3.36 MB)