H/L

Heavy/Light Restraint Straps

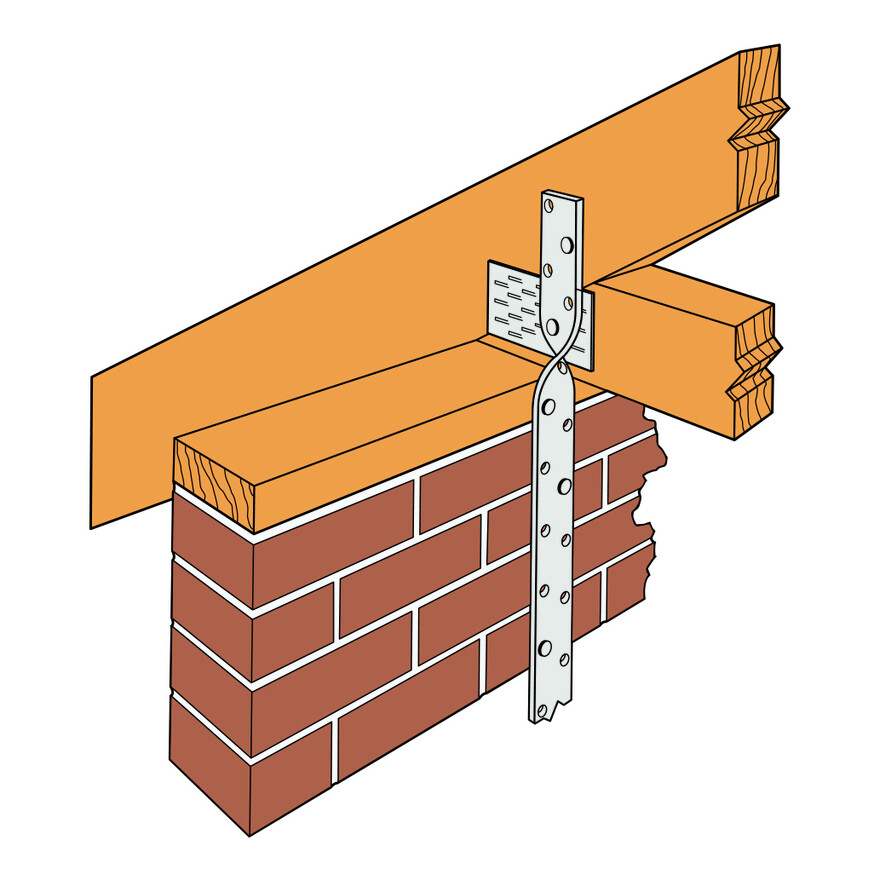

The H and L straps are designed to The Building Regulations for

horizontal and vertical restraint.

- Heavy restraint straps meet requirements for lateral restraint of roof trusses, rafters and joists tied into masonry walls.

- Light restraint straps are designed for vertical loads such as wall plates on top of masonry walls.

- All common sizes in stock from 500 to 2000mm long, 50mm increments. Longer lengths avaialble to order; contact technical support.

CE Marking

Product Details

Features

Material

- Pre-galvanised mild steel

- Stainless steel straps are available, to order

Autres

restraint-strap-order-form.pdf

(376.94 KB)

Technical Data

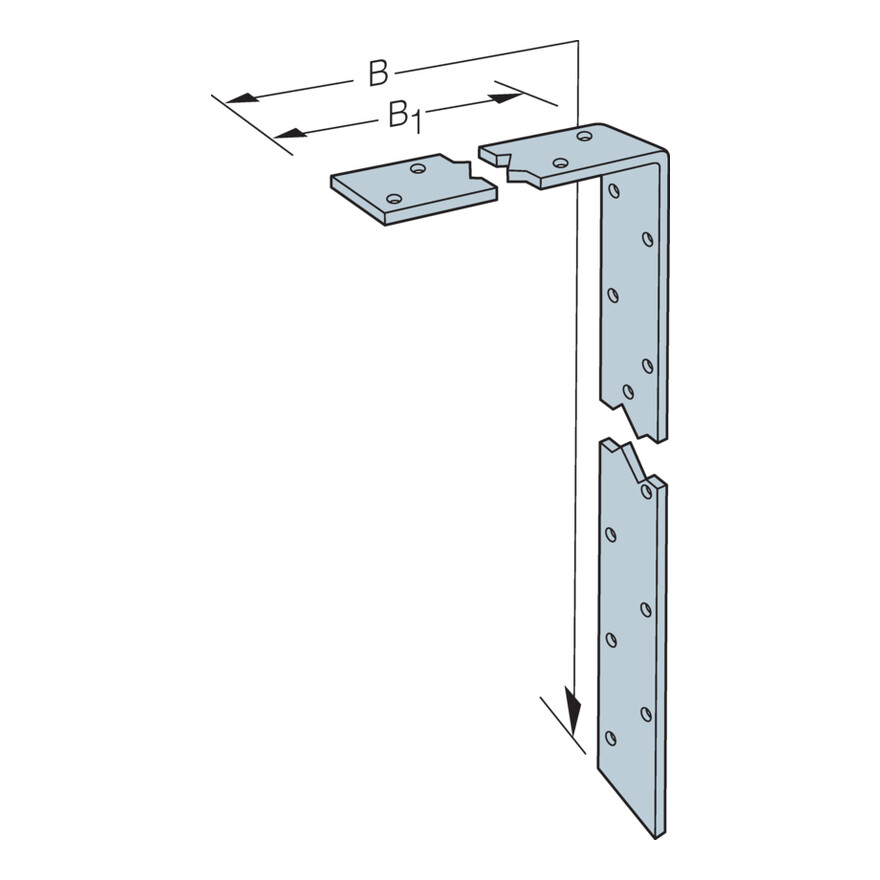

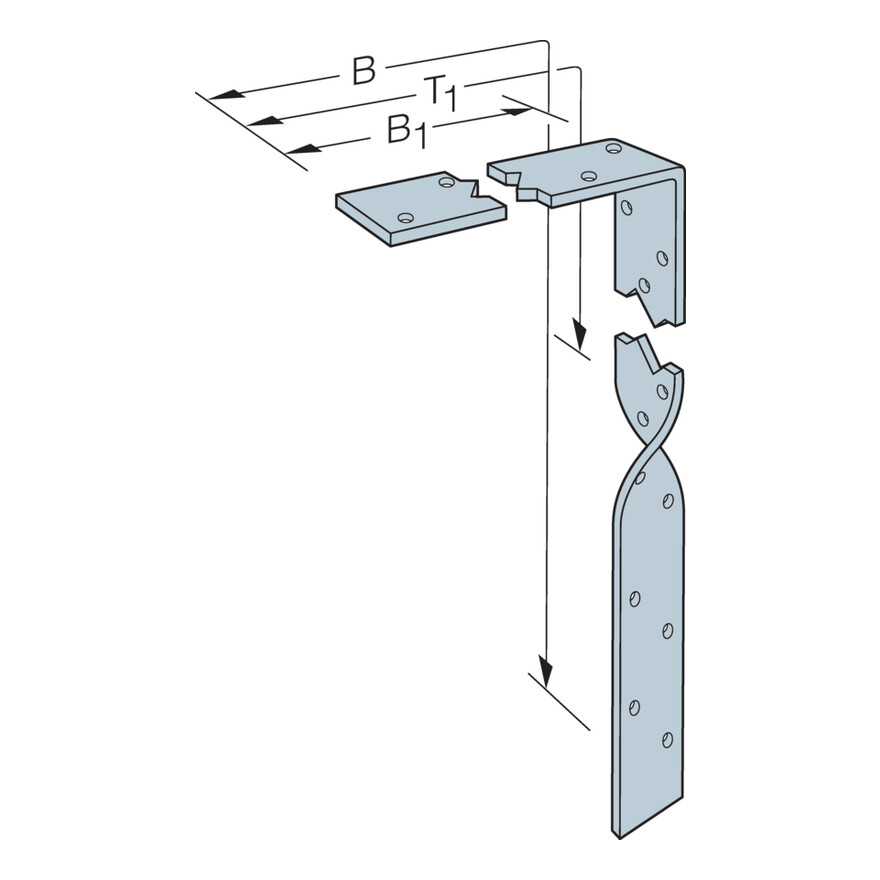

Common Bent Straps

| References | Installation Type | Dimensions [mm] | Holes | |||||

|---|---|---|---|---|---|---|---|---|

| Overall Length [B] | A | B | B1 | t | Total | Flange B1 | ||

| Ø6 | Ø6 | |||||||

| H06B10 | Horizontal | 600 | 28 | 600 | 100 | 4 | 23 | 3 |

| H08B10 | Horizontal | 800 | 28 | 800 | 100 | 4 | 31 | 3 |

| H10B10 | Horizontal | 1000 | 28 | 1000 | 100 | 4 | 39 | 3 |

| H12B10 | Horizontal | 1200 | 28 | 1200 | 100 | 4 | 47 | 3 |

| H15B10 | Horizontal | 1500 | 28 | 1500 | 100 | 4 | 59 | 3 |

| H16B10 | Horizontal | 1600 | 28 | 1600 | 100 | 4 | 63 | 3 |

| H06B15 | Horizontal | 600 | 28 | 600 | 150 | 4 | 23 | 5 |

| H08B15 | Horizontal | 800 | 28 | 800 | 150 | 4 | 31 | 5 |

| H10B15 | Horizontal | 1000 | 28 | 1000 | 150 | 4 | 39 | 5 |

| H12B15 | Horizontal | 1200 | 28 | 1200 | 150 | 4 | 47 | 5 |

| H15B15 | Horizontal | 1500 | 28 | 1500 | 150 | 4 | 59 | 5 |

| H16B15 | Horizontal | 1600 | 28 | 1600 | 150 | 4 | 63 | 5 |

| L06B10 | Vertical | 600 | 28 | 600 | 100 | 2 | 23 | 3 |

| L08B10 | Vertical | 800 | 28 | 800 | 100 | 2 | 31 | 3 |

| L10B10 | Vertical | 1000 | 28 | 1000 | 100 | 2 | 39 | 3 |

| L12B10 | Vertical | 1200 | 28 | 1200 | 100 | 2 | 47 | 3 |

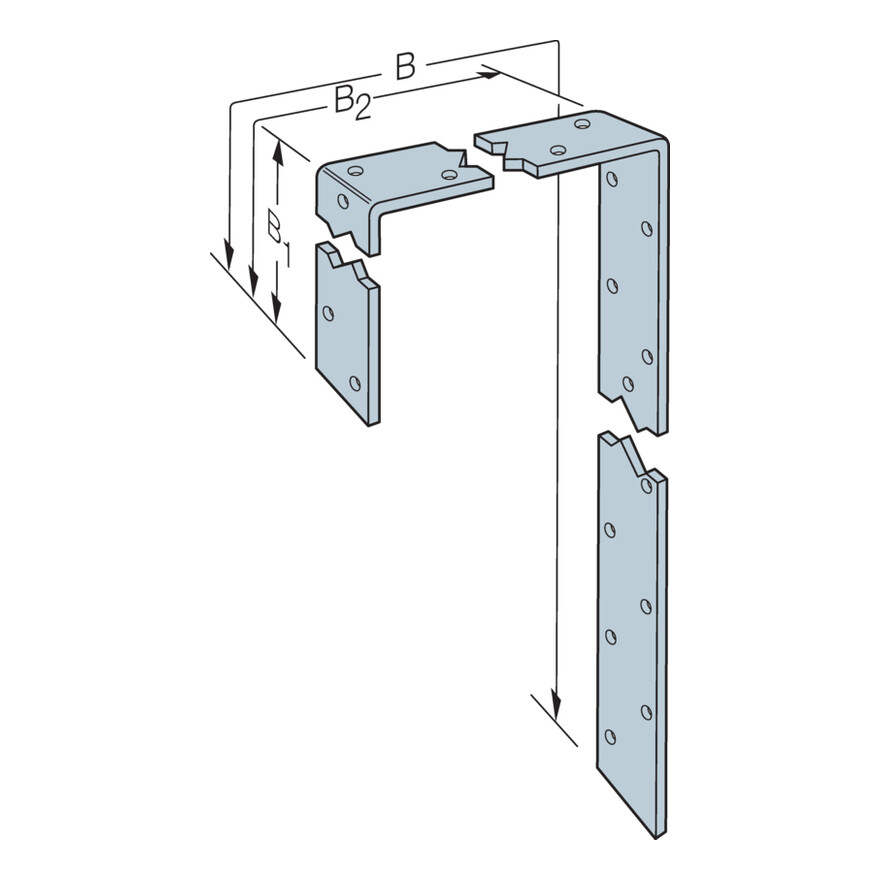

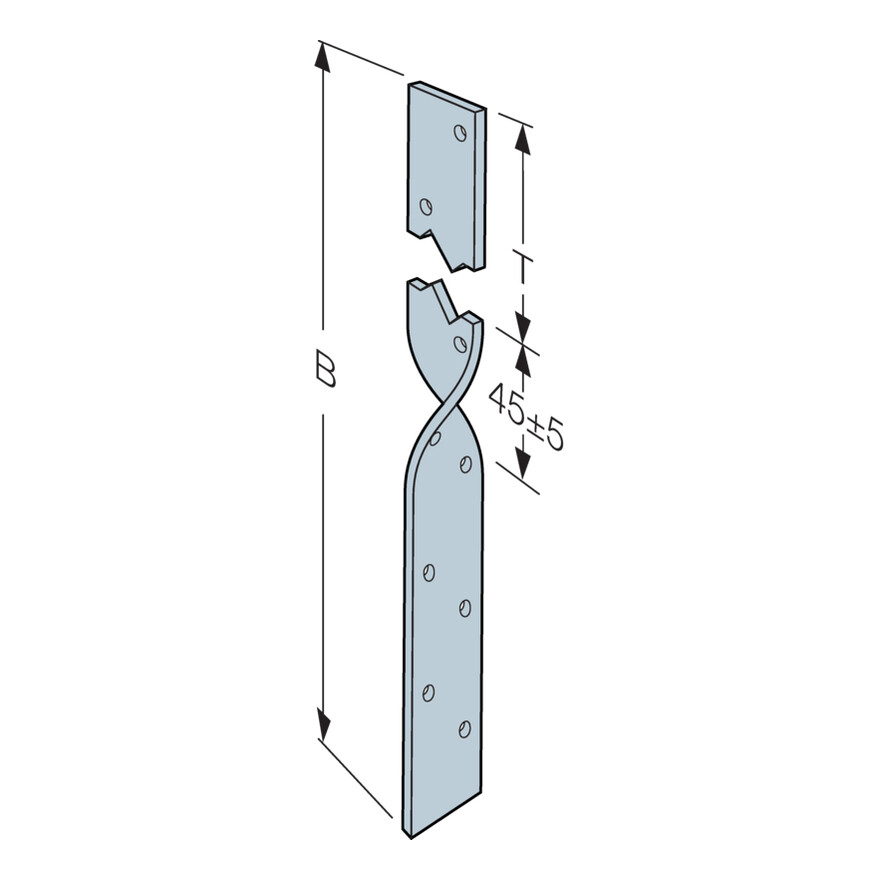

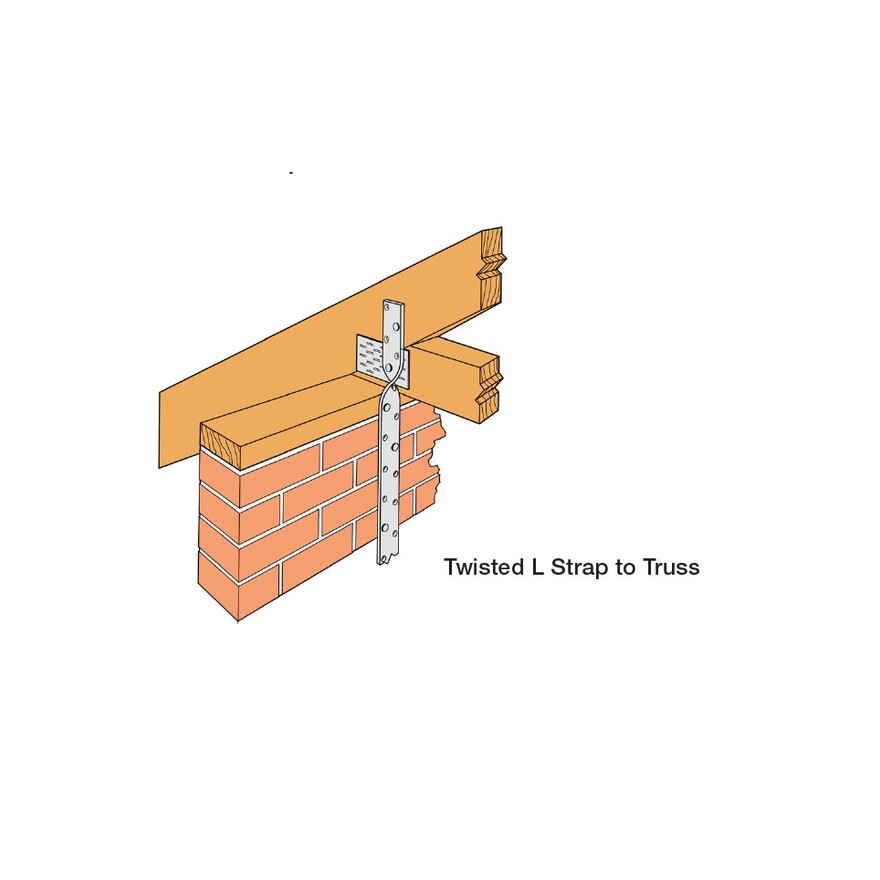

Common Twisted Straps

| References | Dimensions [mm] | Holes | ||||

|---|---|---|---|---|---|---|

| A | B | T1 | t | Total | Flange B1 | |

| Ø6 | Ø6 | |||||

| H06T15 | 28 | 600 | 150 | 4 | 22 | 6 |

| H10T15 | 28 | 1000 | 150 | 4 | 38 | 6 |

| L06T10 | 28 | 600 | 100 | 2 | 22 | 4 |

| L10T10 | 28 | 1000 | 100 | 2 | 38 | 4 |

| L12T10 | 28 | 1200 | 100 | 2 | 46 | 4 |

| L12T15 | 28 | 1200 | 150 | 2 | 46 | 6 |

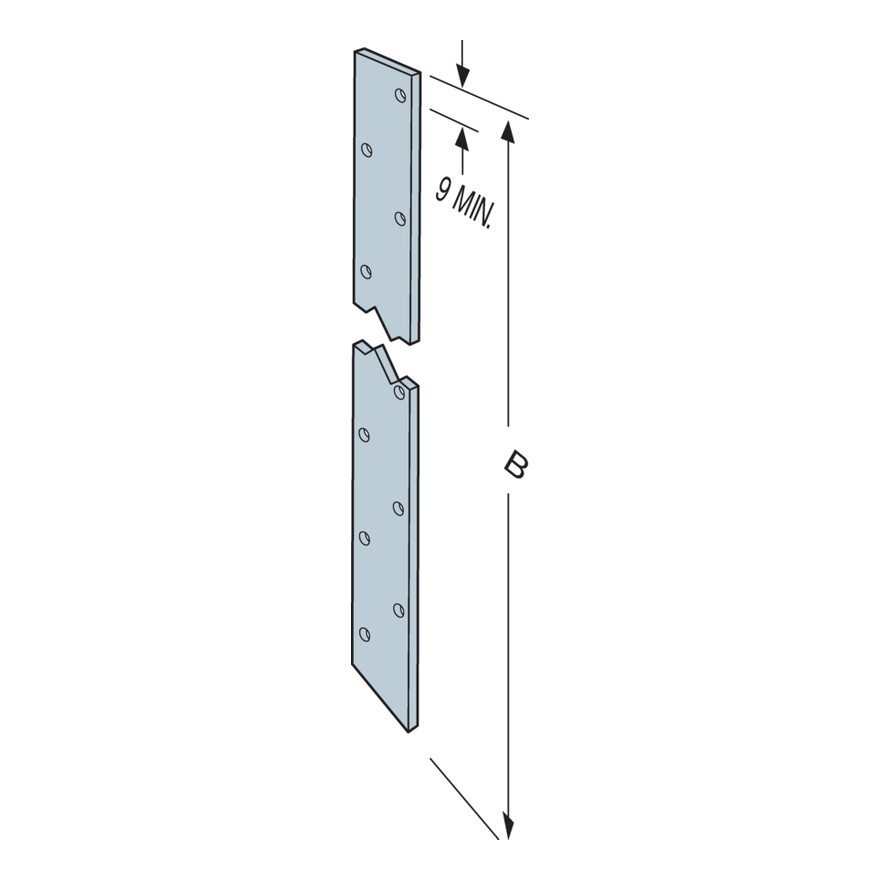

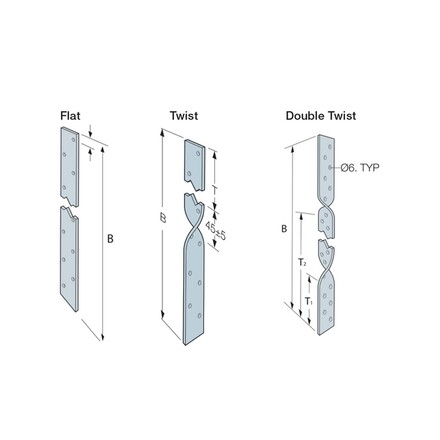

Common Flat Straps

| References | Dimensions [mm] | Holes | |||

|---|---|---|---|---|---|

| Overall Length [B] | A | B | t | Total | |

| Ø6 | |||||

| H10F00 | 1000 | 28 | 1000 | 4 | 40 |

| H12F00 | 1200 | 28 | 1200 | 4 | 48 |

| L10F00 | 1000 | 28 | 1000 | 2 | 40 |

| L12F00 | 1200 | 28 | 1200 | 2 | 48 |

Performance Values

| References | Fasteners | Characteristic Capacity [kN] | ||

|---|---|---|---|---|

| Masonry | Wall Plate | Floor Joist / Rafter | ||

| ø5.5x50 | N3.75x30 | N3.75x30 | ||

| HxxBxx | - | 8 | - | 8 |

| LxxBxx | 5 | - | 3 | 4 |

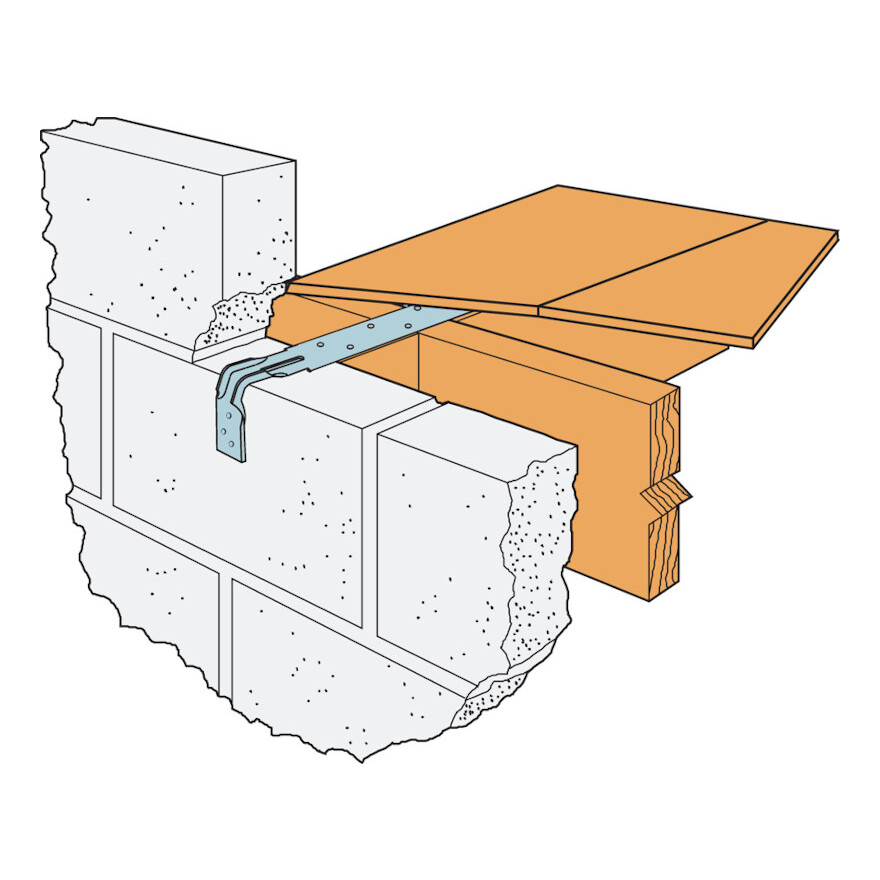

Installation

Installation

Installation

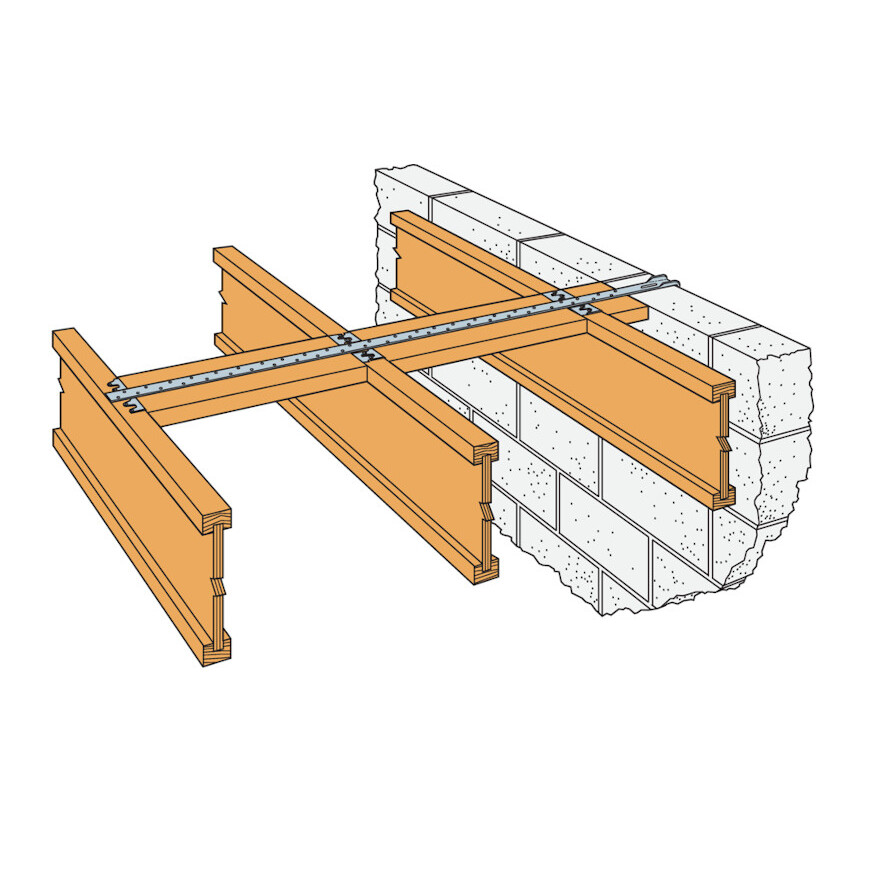

- Use all specified fasteners.

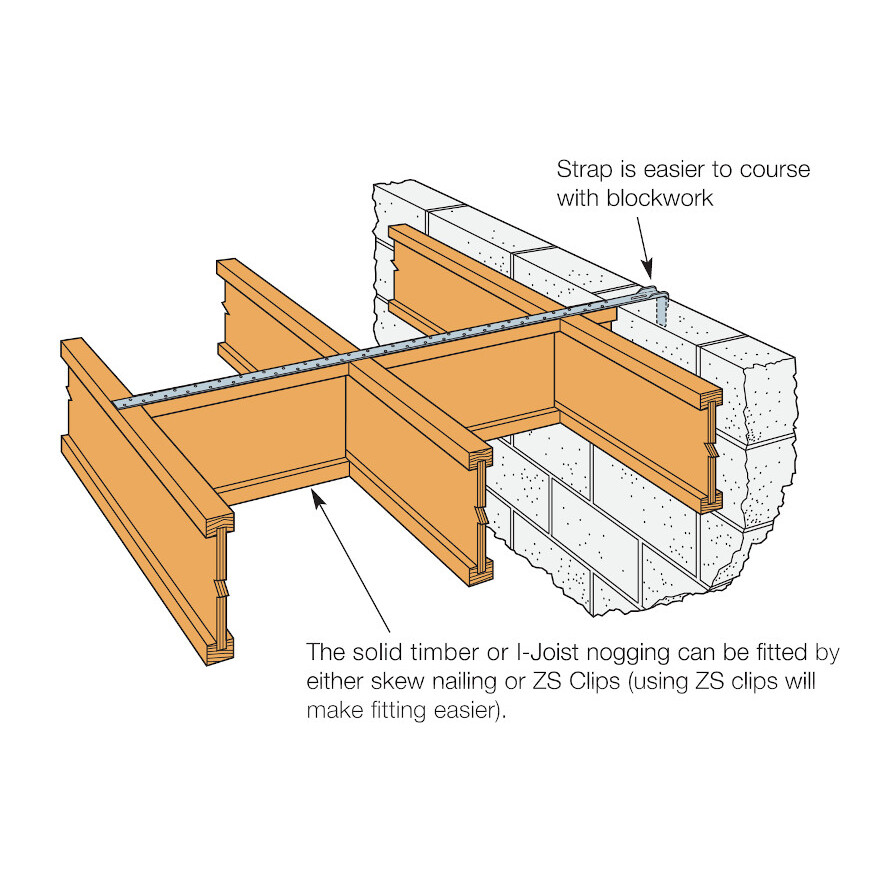

- Horizontal lateral restraint straps should be spaced not more than 2m centres and attached to at least 3 timber members through the use of noggings and packing.

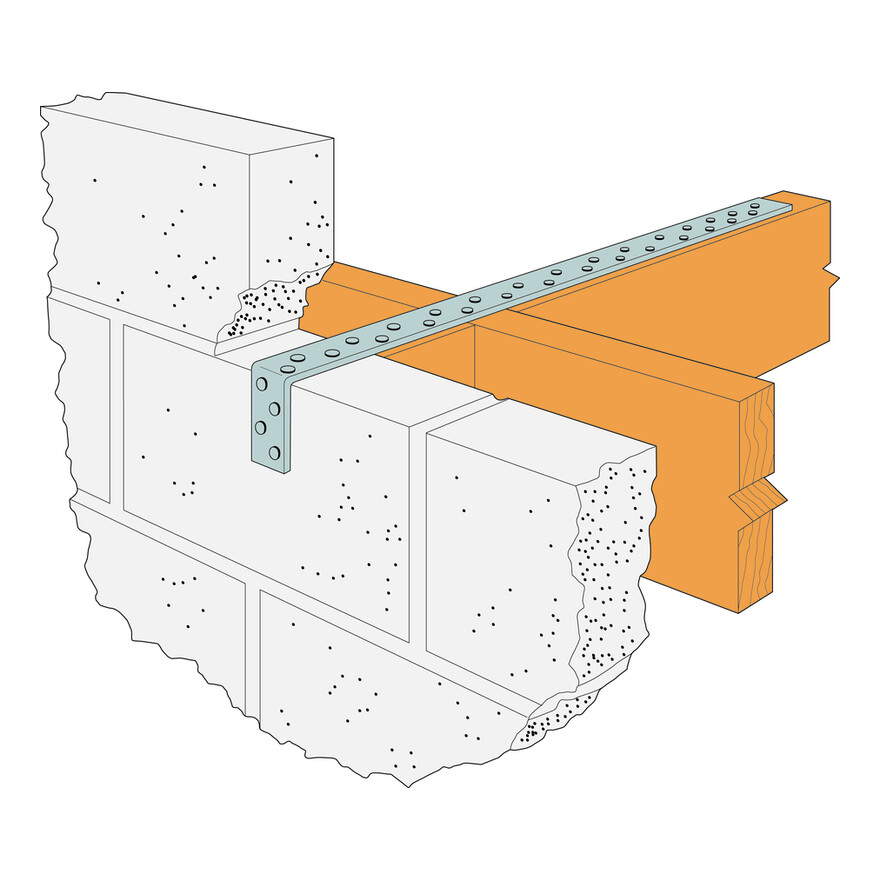

- Attach to timber members using specified fasteners. The bend length should be a minimum of 100mm and should be positioned at the centre of an uncut block or brick.

- Vertical restraint strapping should be at least 1m long.

- Where straps are fixed to masonry, hardened nails Ø4mm x 75mm long or wood screws into plastic plugs Ø5.5 x 50mm long should be used. The lowest fixing should be located within 150mm of the bottom of the vertical strap.

Non standard straps are available to order.

- To order: Specify model series, overall length, bend (B) dimension and/or twist (T) dimension.

- Example: Heavy strap that has an overall length of 1m, a bend at 10cm and a twist at 20cm. (See illustration for detail on measuring bend & twist dimensions).

| H | 10 | B10 | T20 |

Strap Type

| Strap Length (dm) | Bend Length (cm) | Twist Length (cm) |

- Horizontal lateral restraint straps should be spaced not more than 2m centres and attached to at least 3 timber members through the use of noggings and packing.

- Attach to timber members using a minimum of 8 no. 3.75 x 30mm square twist nails. The bend length should be a minimum of 100mm and should be positioned at the centre of an uncut block or brick.

- The downturn of strap is to be held tight against the cavity face of the inner leaf of blockwork.

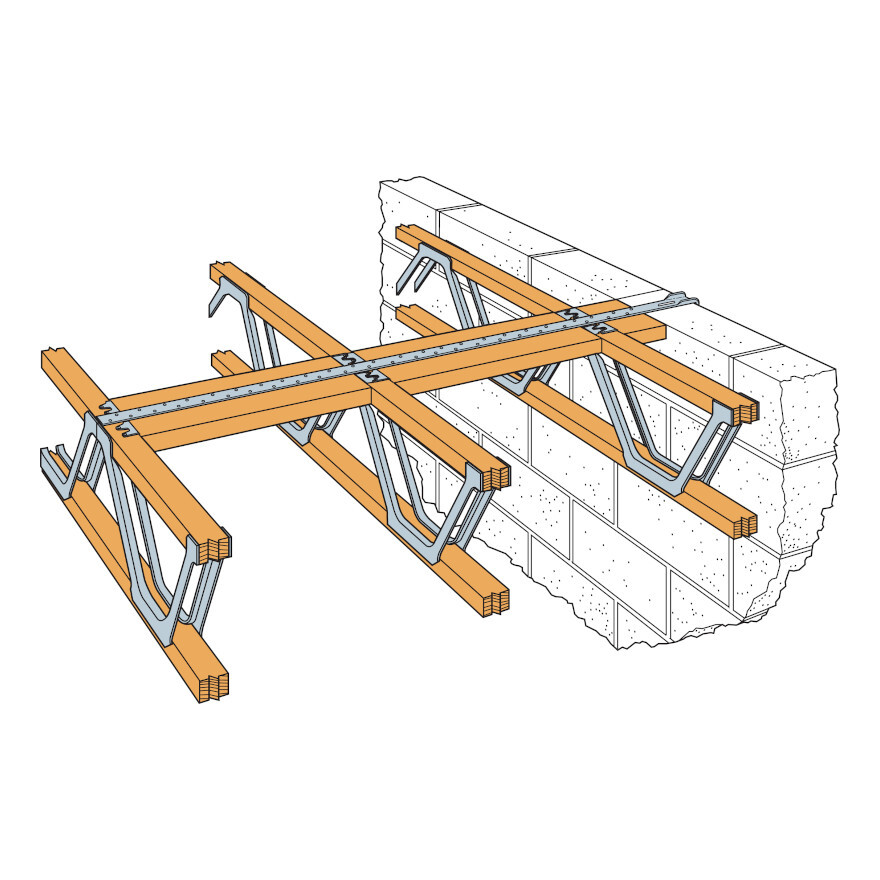

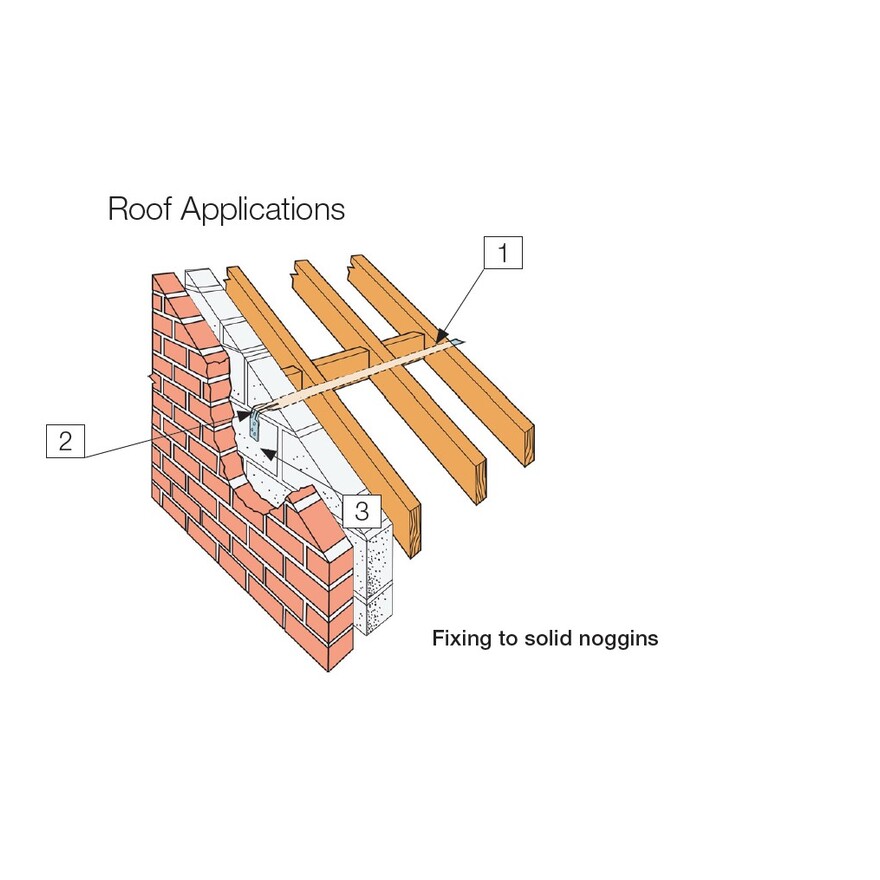

Fixing to solid noggings

- Straps to be installed at not more than 2m centres (or 1.25m where appropriate) along pitch of gable end.

- Ensure the position of the straps coincides with the block bed joint.

- Install HES or H strap to underside of solid noggings. Noggings to be fixed horizontally to avoid twisting of the restraint straps. (1)

- The downturn of strap is to be held tight against the cavity face of the inner leaf of blockwork (2), preferably located and bedded on a substantial piece of blockwork, i.e. over the centre of a full block, with a single cut block over the strap. (3)

- Fix straps to noggings/trusses with eight 3.75 x 30mm square twist nails, evenly distributed along the length of the strap. (For NHBC warrantied buildings, in accordance with NHBC Standards 2017, section 7.2.8, four 50mm (minimum) x 4mm steel screws or four 75mm x 4mm round wire nails, with one fixing into the third rafter, shall be used instead of the square twist nails).

- Strap to be of sufficient length to be fixed to a minimum of three trusses.

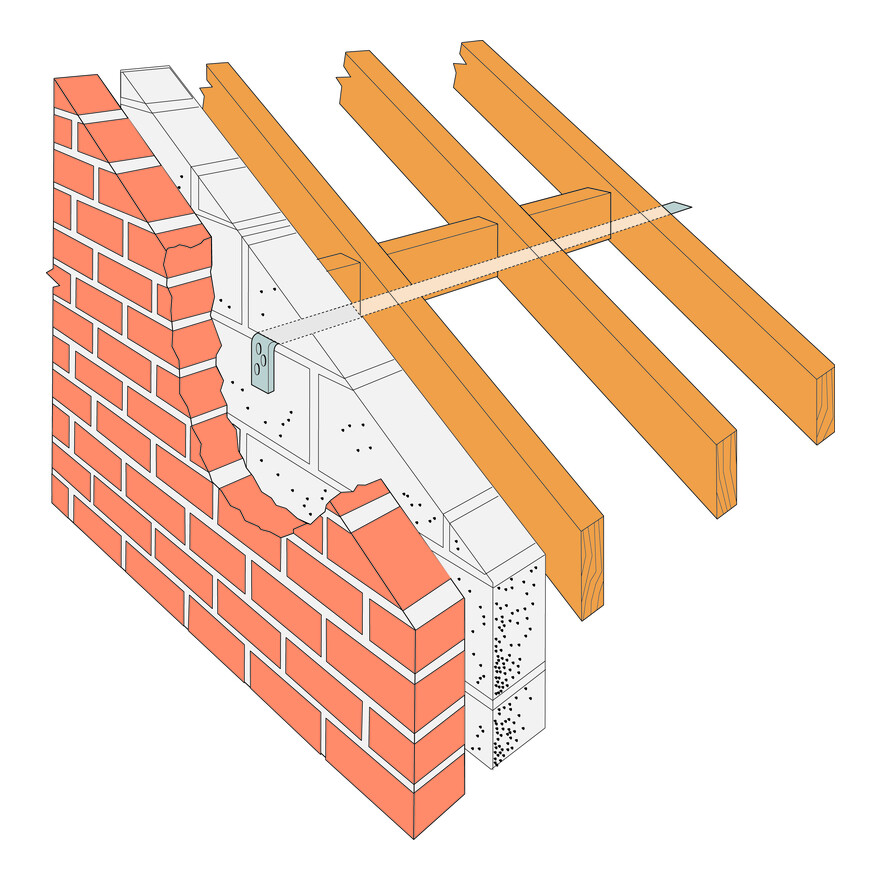

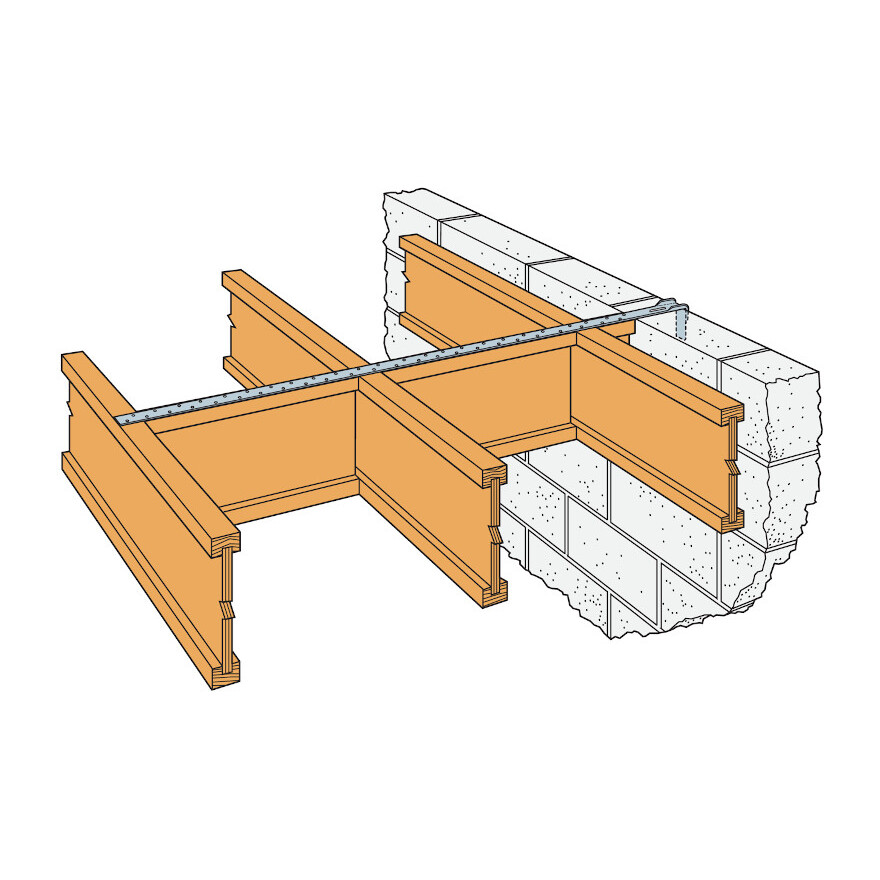

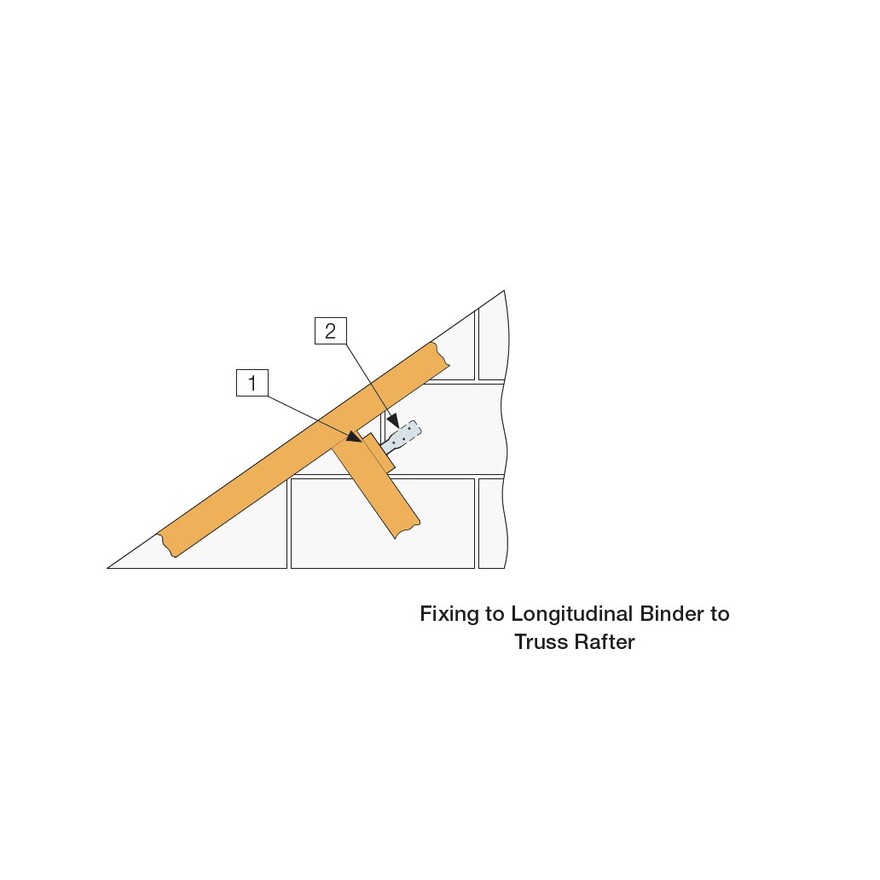

Fixing to longitudinal binder to truss rafter

- Straps to be installed at not more than 2m centres (or 1.25m where appropriate) along pitch of gable end.

- Install HES or H strap on the 25 x 100mm longitudinal Rafter bracing (1).

- Where the position of the strap does not coincide with an existing longitudinal binder, and block bed joint, then the strap can be fixed to an additional 25 x 100mm binder. The binder is to be fixed over four trusses and nailed twice to each rafter with 3.35 x 65mm round wire nails.

- Ensure the position of the additional binder and strap coincide with the block bed joint.

- The downturn of strap is to be held tight against the cavity face of the inner leaf of blockwork (2), preferably located and bedded on a substantial piece of blockwork, i.e. over the centre of a full block, with a single cut block over the strap (3) (notch the block to accommodate the twist of the strap and ensure notch is fully mortared).

- Fix straps to bracing with eight 3.75 x 30mm square twist nails, evenly distributed along the length of the strap (For NHBC warrantied buildings, in accordance with NHBC Standards 2017, section 7.2.8, eight 25mm x 4mm steel screws shall be used instead of the square twist nails).

- Strap to be of sufficient length to be fixed to a minimum of three trusses.

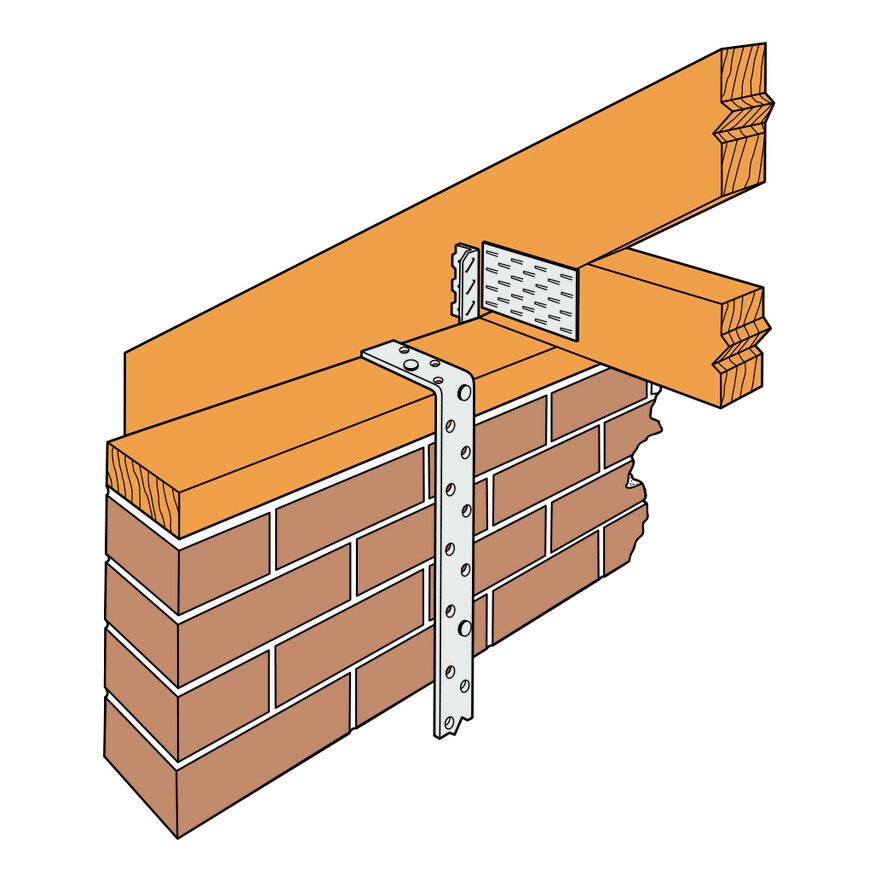

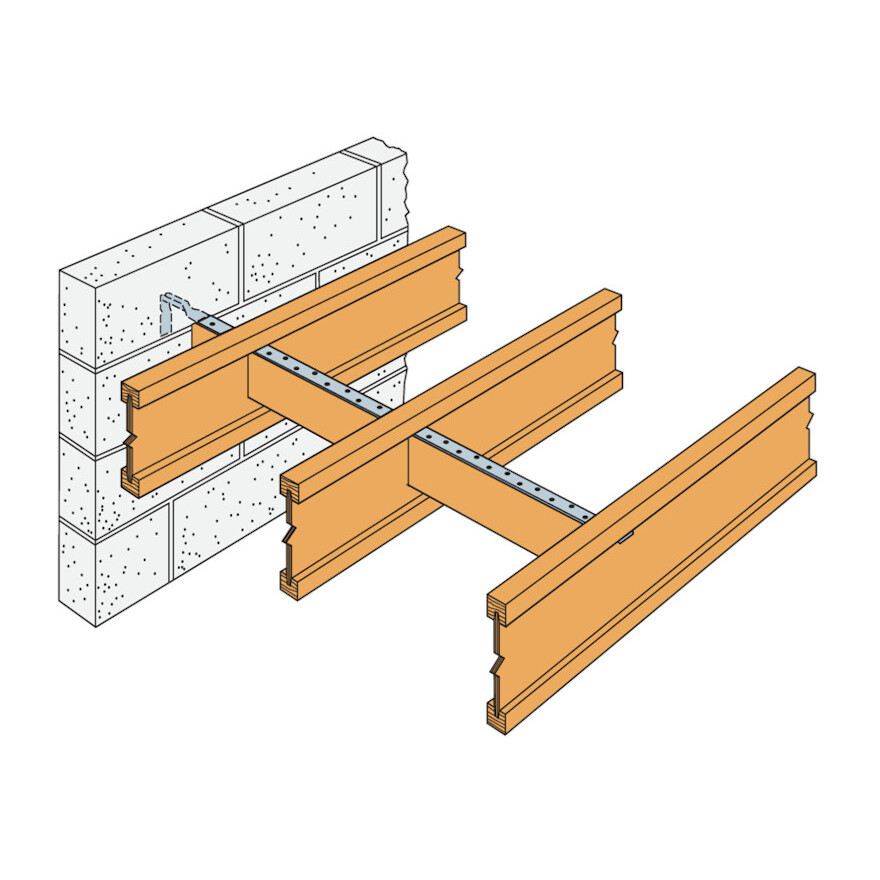

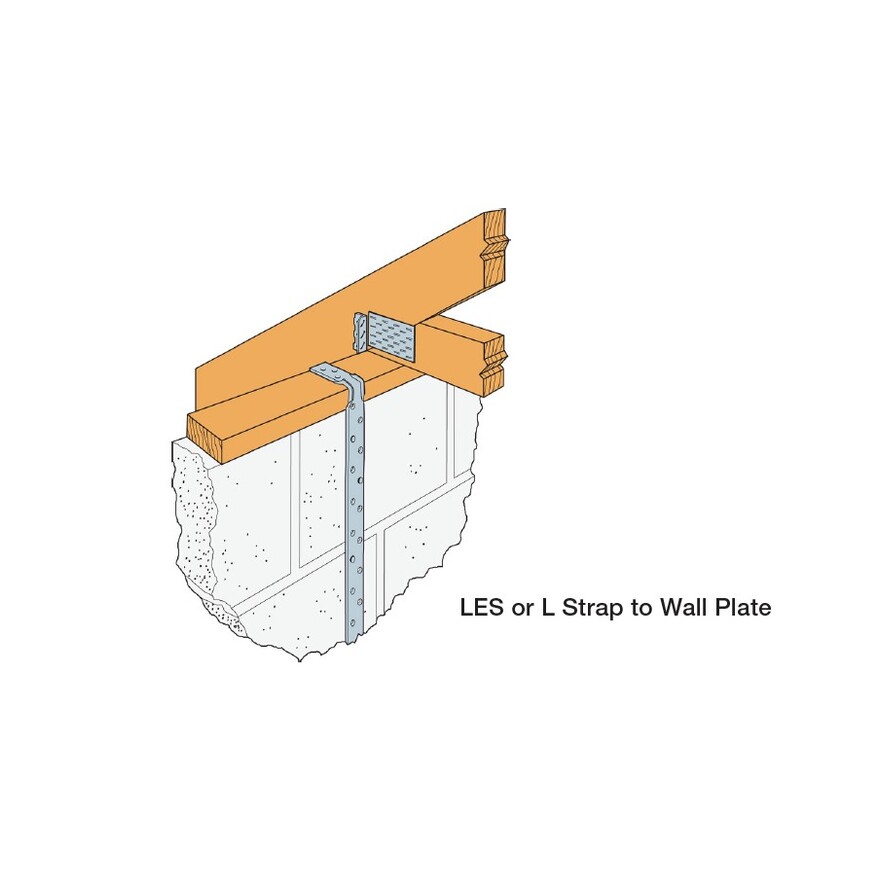

Vertical application

- Fix LES or L strap to wall plate with 3 no. 3.75 x 30mm square twist nails and to masonry with 5 off dia. 5.5 x 50mm wood screws, plugged and screwed into masonry.

- The lowest fixing should be located within 150mm of the bottom of the vertical strap.

- Where L strap is fixed to truss, install with 3.75 x 30mm square twist nails, quantity depending on required uplift values.

Certification

Declaration of Performance (DoP)

uk-dop-h13-0002-pdf.pdf

(41.59 KB)