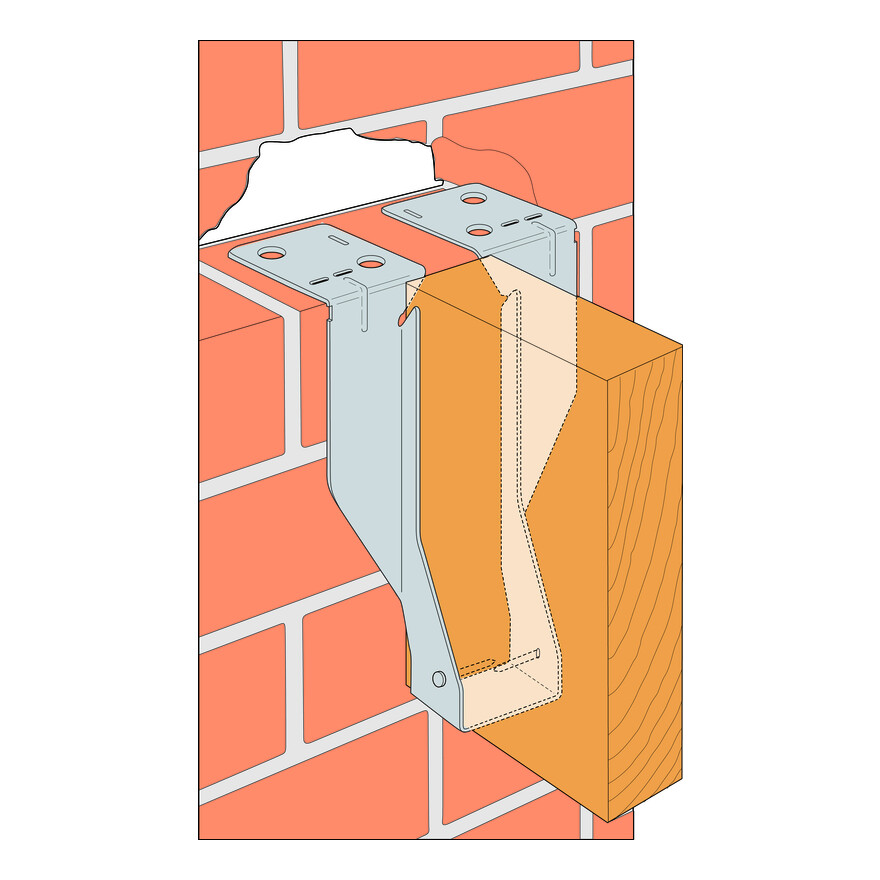

Joist Hanger for Masonry

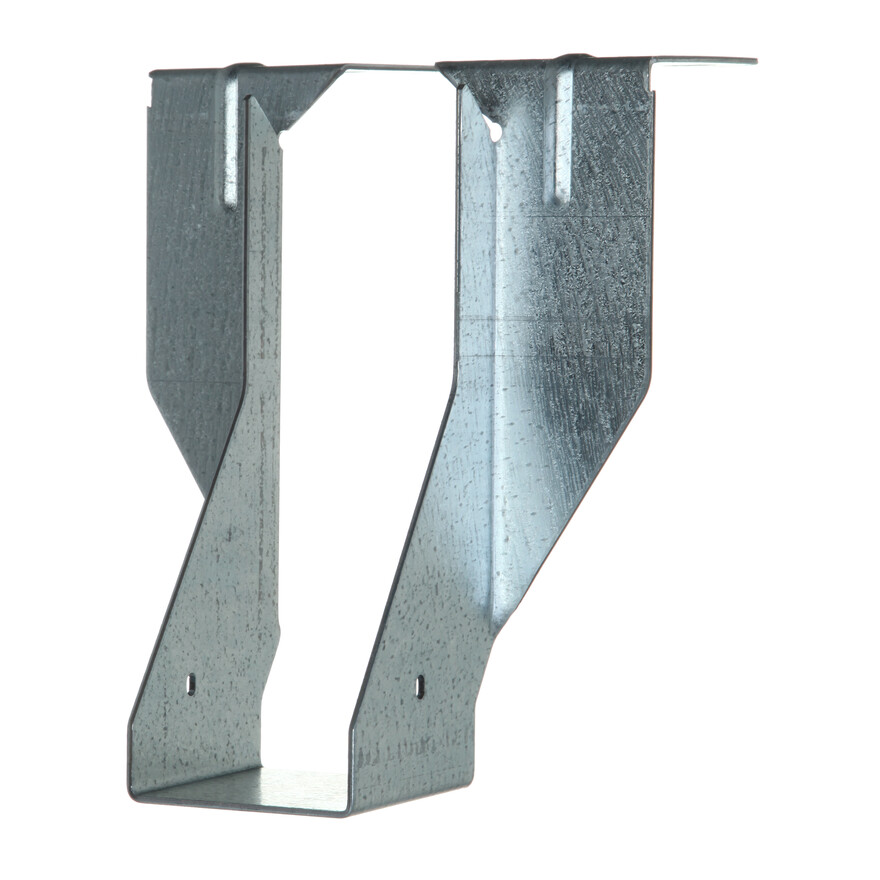

The JHM and JHMI range of joist hangers can be used to connect solid sawn joists, trusses and engineered joists to masonry walls or steel beams.

Product Details

Features

Material

- Pre-galvanised mild steel

Benefits

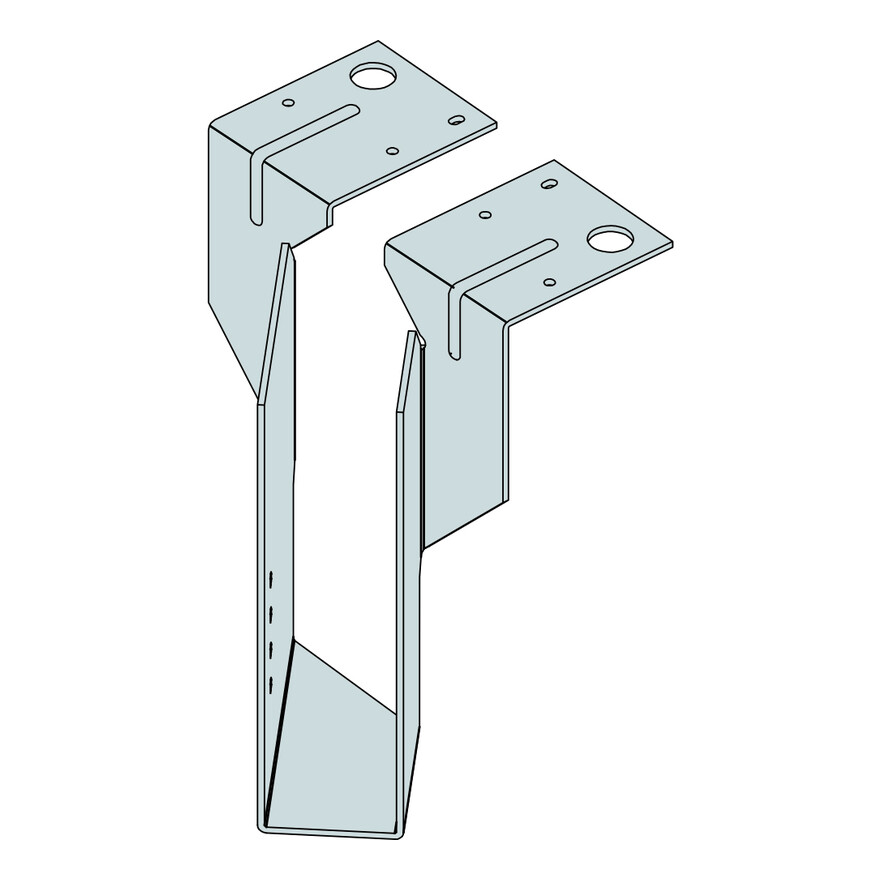

- Built-in inspection slot at the base of the hanger to aid inspection from the ground

- Top flange provides widest area in contact with masonry support allowing superior performance.

- Embossments on JHM stiffen top flange and holes allow improved mortar keying.

- JHM side flange on deeper hangers is much higher than traditional style, providing greatly enhanced resistance to joist rotation.

Additional Installation Options

Technical Data

Product Dimensions

| References | Joist dimensions [mm] | Hanger Dimensions [mm] | Joist holes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Height | A | B | C | D | E | F | t | Ø4 | |

| JHM100/38 | 35 | 100 | 38 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/38 | 35 | 125 | 38 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/38 | 35 | 150 | 38 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/38 | 35 | 175 | 38 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/38 | 35 | 200 | 38 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/38 | 35 | 225 | 38 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/38 | 35 | 250 | 38 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/38 | 35 | 300 | 38 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/44 | 44 | 100 | 44 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/44 | 44 | 125 | 44 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/44 | 44 | 150 | 44 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/44 | 44 | 175 | 44 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/44 | 44 | 200 | 44 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/44 | 44 | 225 | 44 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/44 | 44 | 250 | 44 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/44 | 44 | 300 | 44 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/47 | 47 | 100 | 47 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/47 | 47 | 125 | 47 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/47 | 47 | 150 | 47 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/47 | 47 | 175 | 47 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/47 | 47 | 200 | 47 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/47 | 47 | 225 | 47 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/47 | 47 | 250 | 47 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/47 | 47 | 300 | 47 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/50 | 50 | 100 | 50 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/50 | 50 | 125 | 50 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/50 | 50 | 150 | 50 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/50 | 50 | 175 | 50 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/50 | 50 | 200 | 50 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/50 | 50 | 225 | 50 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/50 | 50 | 250 | 50 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/50 | 50 | 300 | 50 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/63 | 63 | 100 | 63 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/63 | 63 | 125 | 63 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/63 | 63 | 150 | 63 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/63 | 63 | 175 | 63 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/63 | 63 | 200 | 63 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/63 | 63 | 225 | 63 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/63 | 63 | 250 | 63 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/63 | 63 | 300 | 63 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/75 | 2x35 or 75 | 100 | 75 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/75 | 2x35 or 75 | 125 | 75 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/75 | 2x35 or 75 | 150 | 75 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/75 | 2x35 or 75 | 175 | 75 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/75 | 2x35 or 75 | 200 | 75 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/75 | 2x35 or 75 | 225 | 75 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/75 | 2x35 or 75 | 250 | 75 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/75 | 2x35 or 75 | 300 | 75 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/91 | 2x44 or 91 | 100 | 91 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/91 | 2x44 or 91 | 125 | 91 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/91 | 2x44 or 91 | 150 | 91 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/91 | 2x44 or 91 | 175 | 91 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/91 | 2x44 or 91 | 200 | 91 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/91 | 2x44 or 91 | 225 | 91 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/91 | 2x44 or 91 | 250 | 91 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/91 | 2x44 or 91 | 300 | 91 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/96 | 2x47 or 96 | 100 | 96 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/96 | 2x47 or 96 | 125 | 96 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/96 | 2x47 or 96 | 150 | 96 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/96 | 2x47 or 96 | 175 | 96 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/96 | 2x47 or 96 | 200 | 96 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/96 | 2x47 or 96 | 225 | 96 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/96 | 2x47 or 96 | 250 | 96 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/96 | 2x47 or 96 | 300 | 96 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/99 | 99 | 100 | 99 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/99 | 99 | 125 | 99 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/99 | 99 | 150 | 99 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/99 | 99 | 175 | 99 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/99 | 99 | 200 | 99 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/99 | 99 | 225 | 99 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/99 | 99 | 250 | 99 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/99 | 99 | 300 | 99 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/116 | 2x56 or 115 | 100 | 116 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/116 | 2x56 or 115 | 125 | 116 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/116 | 2x56 or 115 | 150 | 116 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/116 | 2x56 or 115 | 175 | 116 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/116 | 2x56 or 115 | 200 | 116 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/116 | 2x56 or 115 | 225 | 116 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/116 | 2x56 or 115 | 250 | 116 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/116 | 2x56 or 115 | 300 | 116 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/125 | 2x63 | 100 | 125 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/125 | 2x63 | 125 | 125 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/125 | 2x63 | 150 | 125 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/125 | 2x63 | 175 | 125 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/125 | 2x63 | 200 | 125 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/125 | 2x63 | 225 | 125 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/125 | 2x63 | 250 | 125 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/125 | 2x63 | 300 | 125 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/135 | 3x45 | 100 | 135 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/135 | 3x45 | 125 | 135 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/135 | 3x45 | 150 | 135 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/135 | 3x45 | 175 | 135 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/135 | 3x45 | 200 | 135 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/135 | 3x45 | 225 | 135 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/135 | 3x45 | 250 | 135 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/135 | 3x45 | 300 | 135 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/142 | 2x70 | 100 | 142 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/142 | 2x70 | 125 | 142 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/142 | 2x70 | 150 | 142 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/142 | 2x70 | 175 | 142 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/142 | 2x70 | 200 | 142 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/142 | 2x70 | 225 | 142 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/142 | 2x70 | 250 | 142 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/142 | 2x70 | 300 | 142 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/146 | 2x72 | 100 | 146 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/146 | 2x72 | 125 | 146 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/146 | 2x72 | 150 | 146 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/146 | 2x72 | 175 | 146 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/146 | 2x72 | 200 | 146 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/146 | 2x72 | 225 | 146 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/146 | 2x72 | 250 | 146 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/146 | 2x72 | 300 | 146 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM100/150 | 3x50 or 2x75 | 100 | 150 | 100 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM125/150 | 3x50 or 2x75 | 125 | 150 | 125 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM150/150 | 3x50 or 2x75 | 150 | 150 | 140 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM175/150 | 3x50 or 2x75 | 175 | 150 | 165 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM200/150 | 3x50 or 2x75 | 200 | 150 | 190 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM225/150 | 3x50 or 2x75 | 225 | 150 | 215 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM250/150 | 3x50 or 2x75 | 250 | 150 | 240 | 64 | 64 | 75 | 75 | 2 | 2 |

| JHM300/150 | 3x50 or 2x75 | 300 | 150 | 290 | 64 | 64 | 75 | 75 | 2 | 2 |

Product Performance - Masonry

| References | Joist Fasteners | Characteristic Capacity [kN] | Safe Working Loads [kN] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Qty | Type | R1,k | R2,k | R1,SWL | R2,SWL,Short Term | |||||

| 2.8N/mm² Solid AAC | 3.5N/mm² Solid LAC | 7.0N/mm² Solid DAC | 2.8N/mm² Solid AAC | 3.5N/mm² Solid LAC | 7.0N/mm² Solid DAC | |||||

| JHM | 2 | N3.75x30 | 10.5 | 12.8 | 20 | 1.8 | 5.2 | 6.4 | 10 | 1 |

Product Performance - Shot fired to Steel Girder

| References | Number of Fasteners | Safe Working Loads [kN] | |||

|---|---|---|---|---|---|

| Header | Joist | R1,SWL,Long Term | |||

| Qty | Type | Qty | Type | ||

| JHM | 4 | Shot fire pins | 2 | N3.75x30 | 5.1 |

1.The above Safe Working Loads are based upon product tests using four No. Hilti 12mm X-EDNI steel pins fired through the top flange material, onto a minimum 4mm thick steel plate. Other pins may be used provided similar structural performance is verified by the pin manufacturer. Pin Head size must be sufficient to prevent pull through during loading.

2.The designer must ensure that the steel support member will support the imposed loads.

3.Install shot-fired pins in accordance with manufacturer’s instructions

Product Performance - Mechanically Fixed to Steel Beam

| References | Number of Fasteners | Safe Working Loads | Characteristic Load [kN] | |||

|---|---|---|---|---|---|---|

| Header | Joist | R1,SWL, Long Term | R1,k | |||

| Qty | Type | Qty | Type | |||

| JHM | 2 | XLQ114B1224 | 2 | N3.75x30 | 10.8 | 19 |

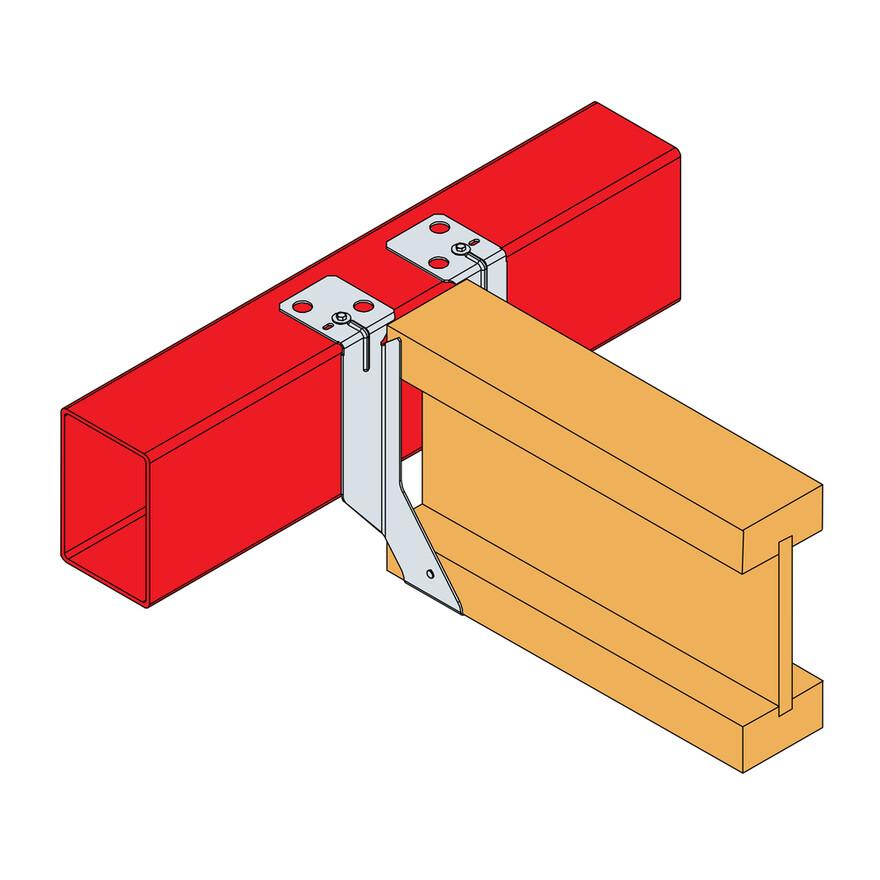

- The designer / engineer must ensure that the steel support can take the imposed loads

- Suitable for Steel I-beams and Hollow Sections upto 12.5mm thick

- Timber is required in the web of steel I-beam when the hanger depth is less than the steel depth. Timber must finish flush with outer edges of steel I-beam

| Fastener Reference | Length [mm] | Hex Head [in] | Washer Diameter [mm] | Shank Diameter [mm] | Suitable Material Thickness [mm] | Recommended Install Speed [rpm] |

| XLQ114B1224 | 32 | 5/16" | 16 | 5.5 | 3.5 - 12.5 | 1400 |

Installation

Installation

Installation

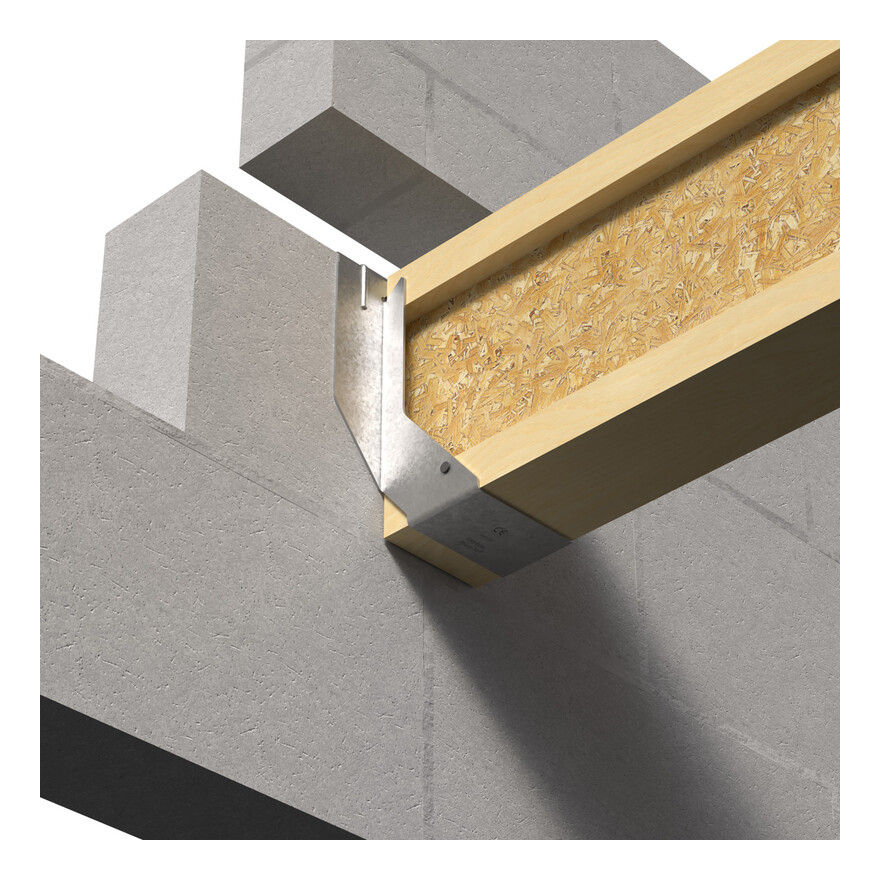

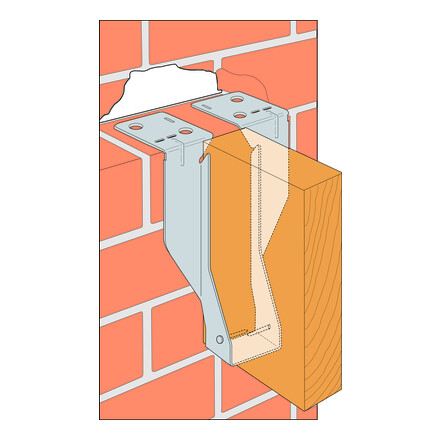

Standard Masonry Installation

- Use all specified fasteners. See "General Notes".

- Set hanger back flange tight against block wall when built to desired level, then continue with additional courses to complete wall height. Joist should be tight into back of hanger when possible. Maximum gap permitted is 6mm.

- MINIMUM 3 COURSES OF SOLID BLOCK (675MM MASONRY) REQUIRED ABOVE HANGER WITH MORTAR FULLY CURED BEFORE APPLYING LOAD.

- Do not stack blocks or heavy loads on the joists during construction unless the joists have additional support to take the full load of the blocks vertically and horizontally.

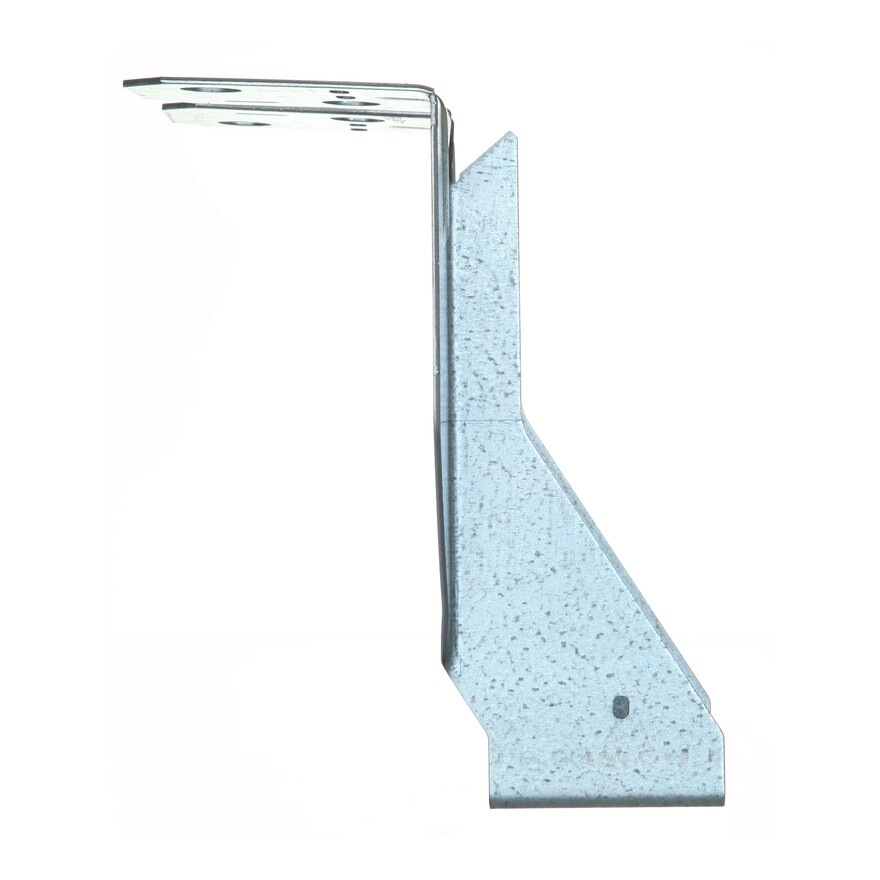

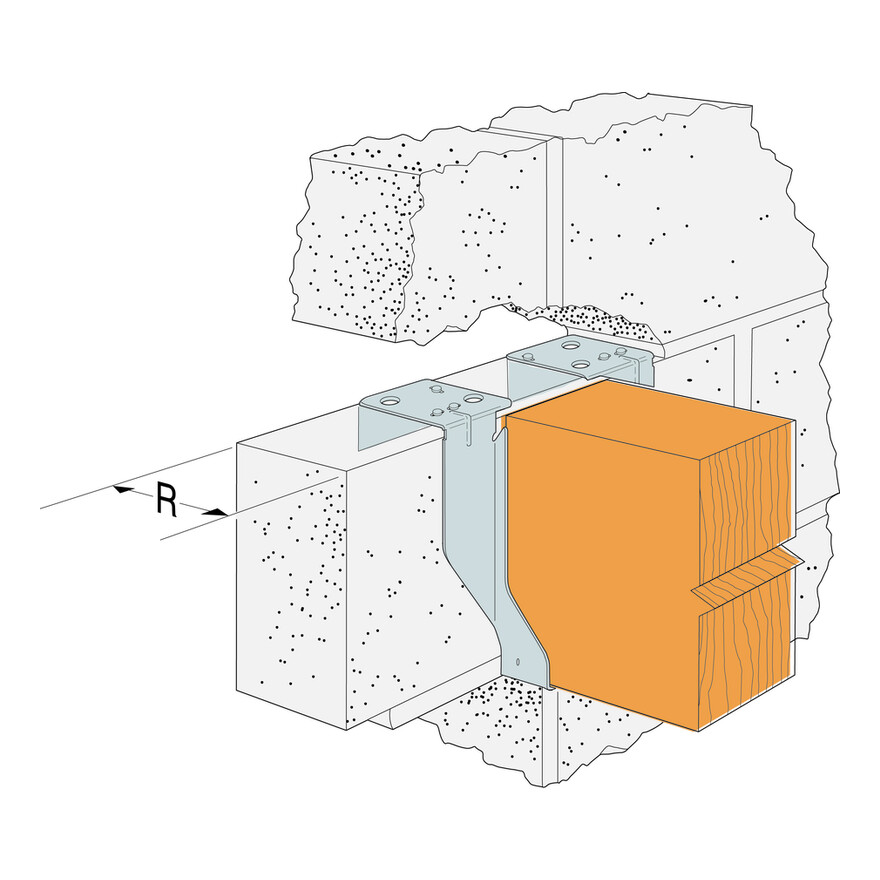

Fixed to Steel Beams

- The JHM range can be mechanically fixed to steel beams of

thicknesses up to 12.5mm. - Timber is required in the web of the ‘I’ section steel beam when

the hanger depth is less than the steel depth. - Timber must be flush with the outer edges of the ‘I’ section steel

beam. - The shot-fired pins must be installed by a qualified person in accordance with the manufacturer’s installation requirements.

Options

Options

- Return configuration provides additional support by wrapping around three sides of the block. Designate "return" and length of return dimensions when ordering.

- JHM, JHMR OR JHMS HANGERS DO NOT SATISFY THE REQUIREMENTS FOR LATERAL RESTRAINT TYPE HANGERS UNLESS STRAPS ARE FITTED.

- Straddle configuration provides two hangers connected across top of support enabling exact alignment on both sides of supporting wall. Designate "straddle" and length of straddle dimensions when ordering.

- Other widths and heights available to order. Contact Simpson Strong-Tie® for details.

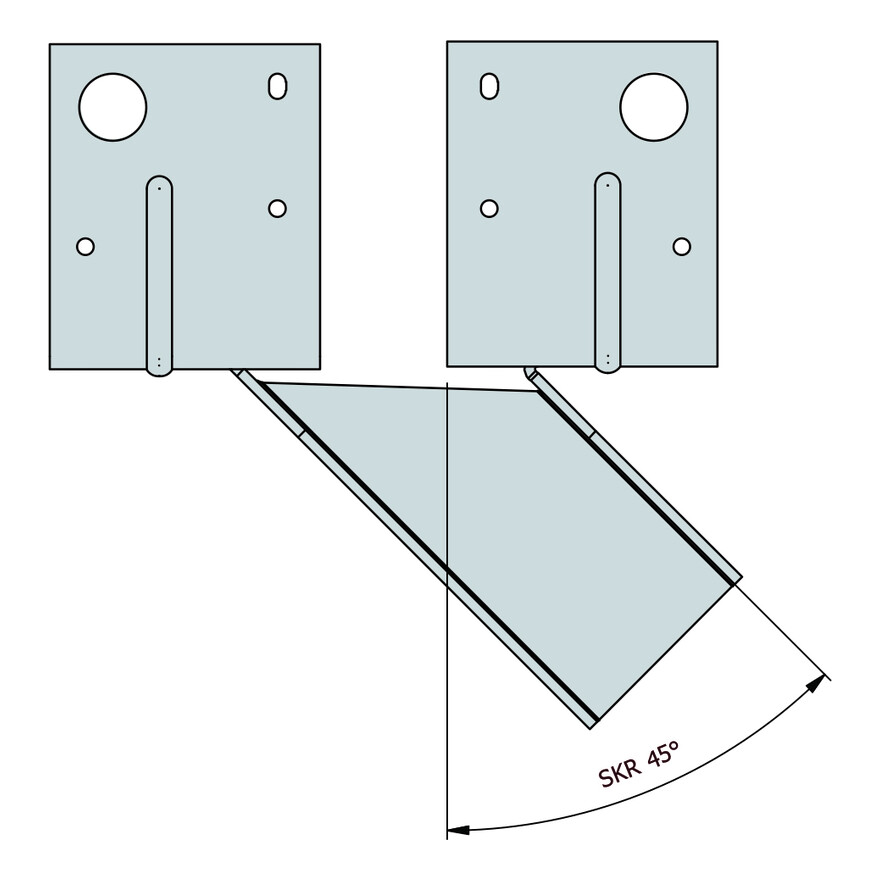

- SPEC JHM’s up to 61mm width can be skewed from 5 to 45 deg. See skewed hanger load table.