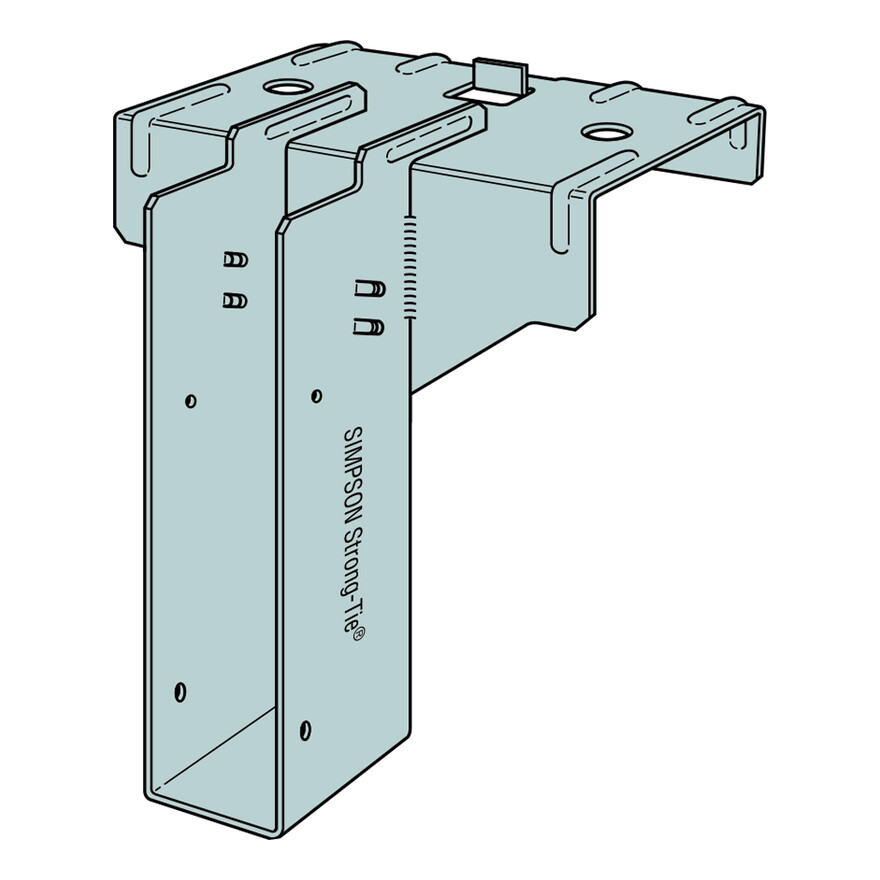

SFWH

Safety Fast (Welded) Hanger for Solid Joists

The SFWH Safety Fast Hangers are designed to support timber joists, beams and trussed rafters from masonry walls without the need for masonry above the top flange.

CE Marking

Product Details

Features

Benefits

Requires no masonry above the top flange to achieve the published performance values.

- Improved vertical and lateral load distribution.

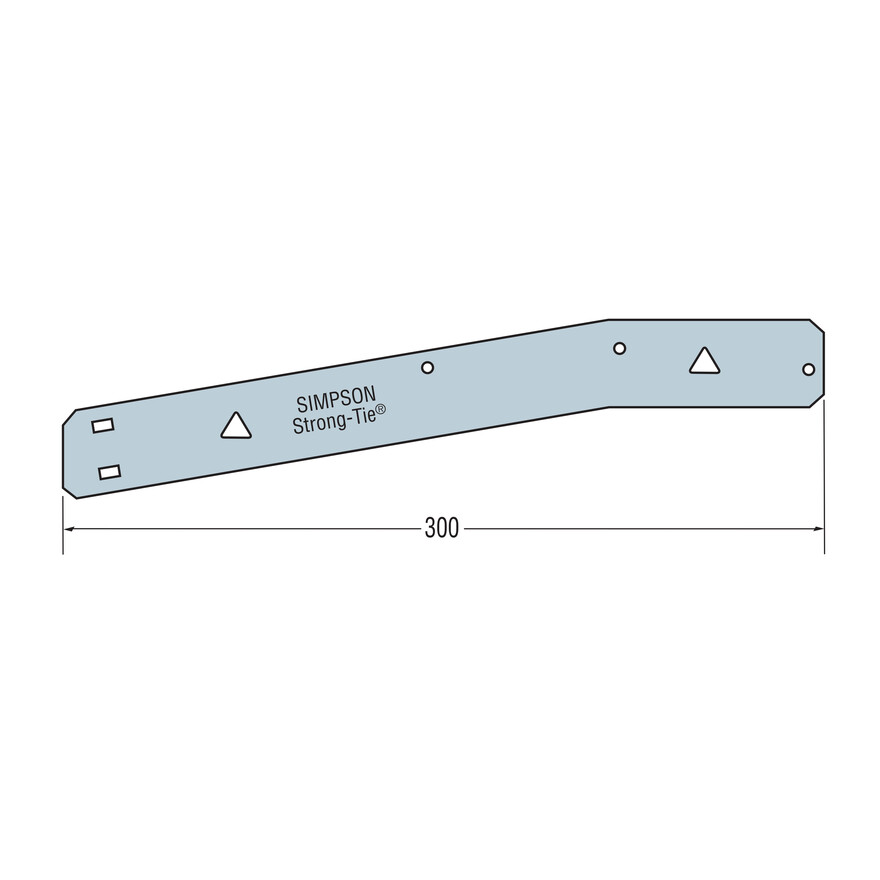

- Mini Strap simply hooks onto the hanger.

- Enables the construction of the floor deck prior to the next lift of masonry.

- Reduces Health & Safety risks associated with the use of traditional masonry hangers with no masonry above.

- Eliminates the need for propping of floor joists.

- Mini Strap provides lateral restraint capacity in accordance with NHBC guidelines.

- Allows for retrofit of lateral restraint straps.

Material

- SFWH/SFWHI: Hot-dip galvanised mild steel

- Mini Strap: Pre-galvanised mild steel

Technical Data

Product Dimensions

| References | Product Dimensions [mm] | Joist holes | Mini Strap holes | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | t | Ø6x4 Oblong [mm] | Ø4.1 [mm] | Ø4.2 [mm] | |

| SFWH225/38/100 | 38 | 215 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/44/100 | 44 | 215 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/44/100 | 44 | 240 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/47/100 | 47 | 100 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/47/100 | 47 | 125 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/47/100 | 47 | 140 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/47/100 | 47 | 165 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/47/100 | 47 | 190 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/47/100 | 47 | 215 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/47/100 | 47 | 240 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/47/100 | 47 | 290 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/50/100 | 50 | 100 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/50/100 | 50 | 125 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/50/100 | 50 | 140 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/50/100 | 50 | 165 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/50/100 | 50 | 190 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/50/100 | 50 | 215 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/50/100 | 50 | 240 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/50/100 | 50 | 290 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/75/100 | 75 | 100 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/75/100 | 75 | 125 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/75/100 | 75 | 140 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/75/100 | 75 | 165 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/75/100 | 75 | 190 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/75/100 | 75 | 215 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/75/100 | 75 | 240 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/75/100 | 75 | 290 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/91/100 | 91 | 100 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/91/100 | 91 | 125 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/91/100 | 91 | 140 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/91/100 | 91 | 165 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/91/100 | 91 | 190 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/91/100 | 91 | 215 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/91/100 | 91 | 240 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/91/100 | 91 | 290 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/99/100 | 99 | 100 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/99/100 | 99 | 125 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/99/100 | 99 | 140 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/99/100 | 99 | 165 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/99/100 | 99 | 190 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/99/100 | 99 | 215 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/99/100 | 99 | 240 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/99/100 | 99 | 290 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/116/100 | 116 | 100 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/116/100 | 116 | 125 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/116/100 | 116 | 140 | 75 | 200 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/125/100 | 125 | 165 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/125/100 | 125 | 190 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/125/100 | 125 | 215 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/125/100 | 125 | 240 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/125/100 | 125 | 290 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/135/100 | 135 | 100 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/135/100 | 135 | 125 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/135/100 | 135 | 140 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/135/100 | 135 | 165 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/135/100 | 135 | 190 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/135/100 | 135 | 215 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/135/100 | 135 | 240 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/135/100 | 135 | 290 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/150/100 | 150 | 100 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/150/100 | 150 | 125 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/150/100 | 150 | 140 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/150/100 | 150 | 165 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/150/100 | 150 | 190 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/150/100 | 150 | 215 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/150/100 | 150 | 240 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/150/100 | 150 | 290 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/180/100 | 180 | 100 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH100/200/100 | 200 | 100 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH125/200/100 | 200 | 125 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH150/200/100 | 200 | 140 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH175/200/100 | 200 | 165 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH200/200/100 | 200 | 190 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH225/200/100 | 200 | 215 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH250/200/100 | 200 | 240 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

| SFWH300/200/100 | 200 | 290 | 75 | 275 | 103 | 2.5 | 2 | 2 | 3 |

Product Capacities - Timber to Masonry

| References | Number of Fasteners | Characteristic Capacities [kN] | Safe Working Loads [kN] | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Joist | Mini Strap | R1.k | R1,SWL | ||||||

| Qty | Type | Qty | Type | 3.5N/mm2 Solid LAC | 7N/mm2 Solid DAC | 3.5N/mm2 Solid AAC | 2.8N/mm2 Solid LAC | 7N/mm2 Solid DAC | |

| SFWH (A ≤ 63mm) | 2 | N3.75x30 | 3 | N3.75x30 | 18.6 | 18.6 | 9.3 | 7.4 | 9.3 |

| SFWH (A > 63mm) | 2 | N3.75x30 | 3 | N3.75x30 | 28.9 | 28.9 | 14.5 | 11.6 | 14.5 |

Installation

Installation

Installation

Use all specified nails.

- Build masonry to required level, ensuring any coursing bricks or blocks are at least one course below the supporting block, and leave to cure.

- Place the Safety Fast Restraint Hanger over the inner leaf of block work, ensuring the bearing plate is fully located onto the top of the masonry, sitting tight against the front face and top of the block work.

- Sit the floor joist into the masonry hanger and ensure all joists are correctly installed. The joist should be tight into the back of the hanger where possible. The maximum gap between the back of the hanger and the end of the joist is 6mm. Use specified nails.

- Clip the Safety Fast Mini Strap onto the restraining hooks on either side of the hanger and nail to the side face of the joist with 3.75 x 30mm square twist nails. INSTALL ONLY ONE STRAP PER HANGER.

General Installation Notes

- The floor decking may be stored on the joists provided the load is uniformly distributed between the several joists and does not exceed the hanger or joist capacities. Refer to joist manufacturer or supplier for joist capacity and maximum construction loads.

- The floor decking must be securely attached to each joist before additional loads can be placed on the system.

- Floor decking and block work is to be cut where necessary to fit around the upstand stiffeners.

- Pallets of blocks or other construction materials should be placed onto the scaffolding and NOT directly onto the floor.

- The materials can then be evenly distributed around the floor manually, ensuring hanger or joist capacities are not exceeded.