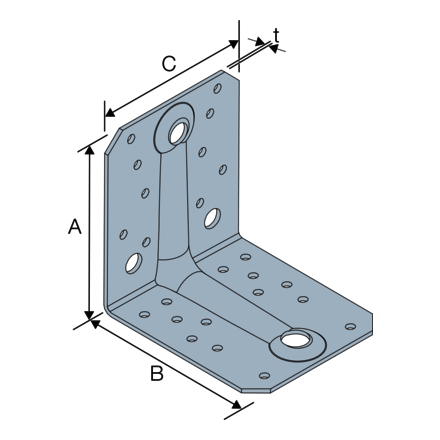

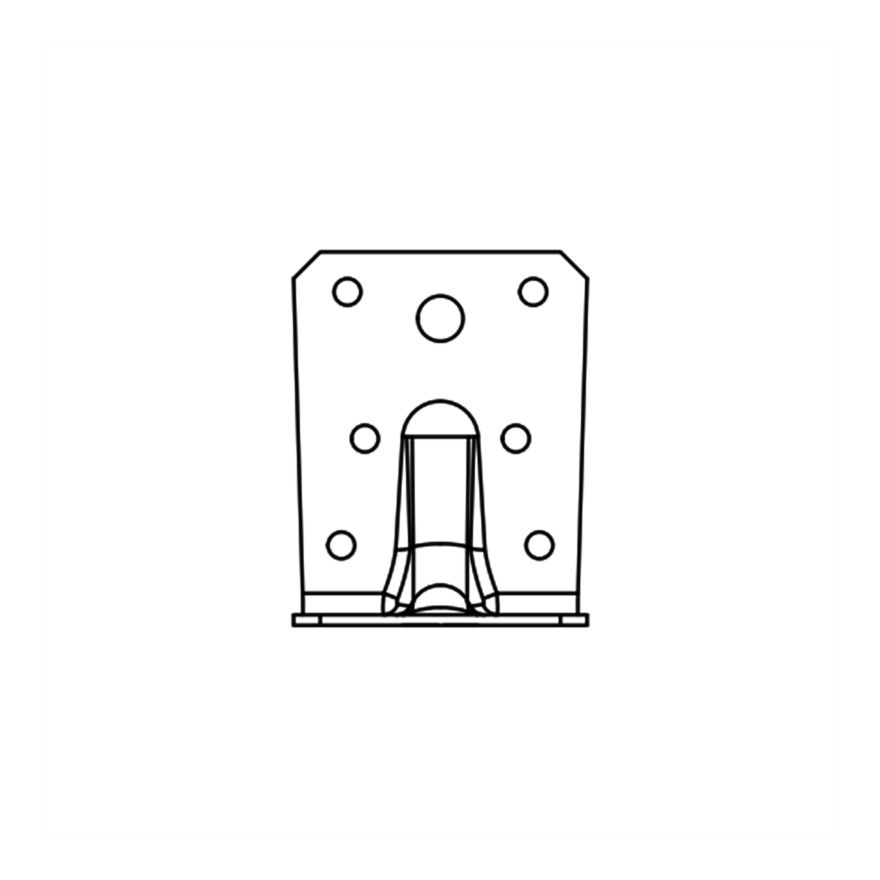

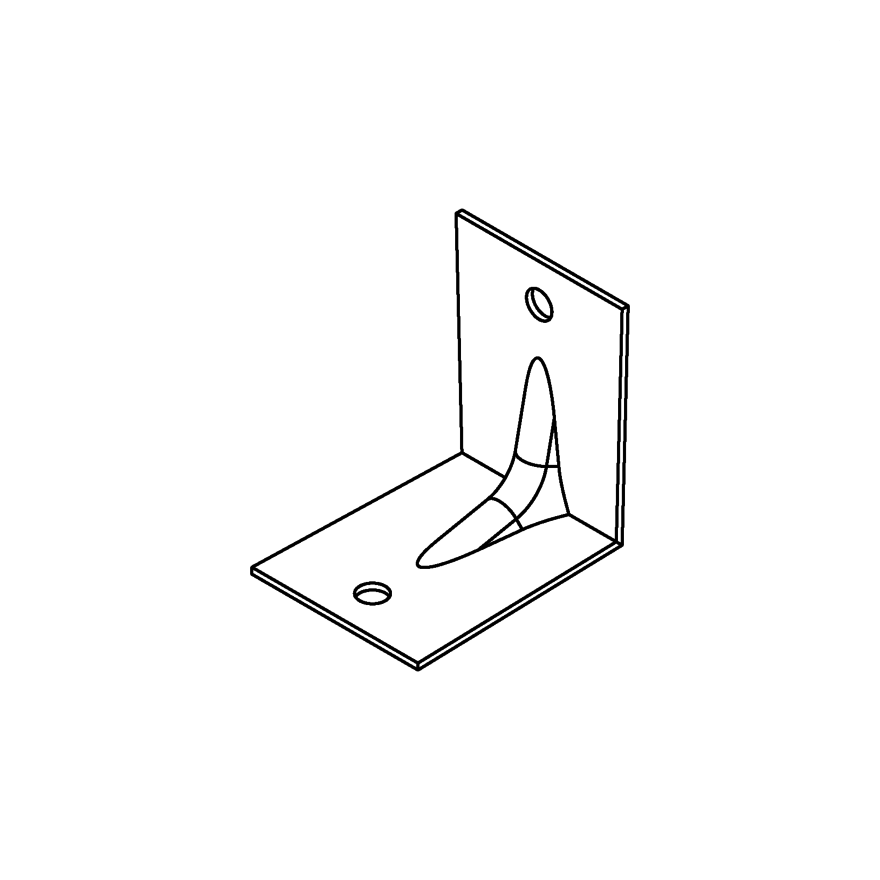

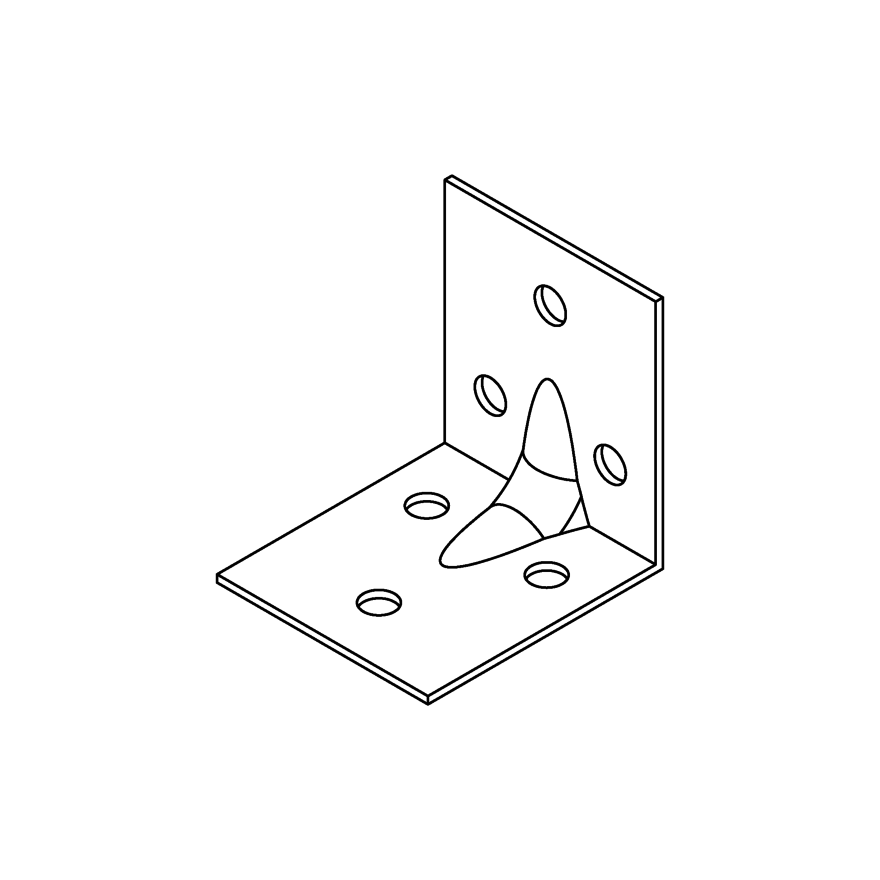

Reinforced Angle Bracket (105-R)

Reinforced angle brackets are suitable for structural applications in framing and wood-frame houses.

Product Details

Features

Material

- Pre-galvanised mild steel.

Benefits

- Load capacity in all directions

- Improved capacities for full and partial nailing

Application

Suitable On

- Supporting member: solid wood, glued-laminated wood, concrete, steel, etc.

- Supported member: solid wood, composite lumber, glued-laminated wood, triangular trusses, profiles, etc.

When to Use

- Fastening of small trusses.

- Cladding plates, cladding uprights.

- Rafter anchors, cantilevers, headers, etc.

Technical Data

Product capacities - Timber to timber - Full nailing - 2 angles brackets

| References | Product capacities - Timber to timber - Full nailing | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Fasteners | Characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | |||||||||||||

| Joist | Flange B | R1.k | R2.k = R3.k | R4.k = R5.k* | ||||||||||

| Qty | Qty | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |

| ABR70 | 4 | 6 | 4.38 | 5.34 | 7.11 | 8.89 | 4.55 | 5 | 6.89 | 7.33 | - | 3,0 / kmod^0,5 | - | - |

| ABR90 | 8 | 10 | 6.46 | 7.87 | 10.66 | 13.32 | 8.38 | 9.21 | 11.07 | 11.78 | - | 8,1 / kmod^0,85 | - | 9,1 / kmod^0,75 |

| ABR105 | 10 | 14 | 8.84 | 10.78 | 14.33 | 17.91 | 13.26 | 14.57 | 19.01 | 20.22 | - | 12,9 / kmod^0,5 | - | 14,5 / kmod^0,75 |

* b = 75 mm and e = 130 mm

To obtain the resistance values for a single bracket, the values in the above table should be divided by two, provided that the supported beam is locked in rotation. Please consult our ETA-06/0106 if the beam is free to rotate.

Simplified product capacities - Timber to rigid support - 2 angles brackets

| References | Simplified product capacities - Timber to Concrete | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Fasteners | Simplified characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | |||||||||||

| Joist | Flange B | R1.k* | R2.k = R3.k | |||||||||

| Qty | Type | Qty | Type | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |

| ABR105 | 10 | CNA | 1 | Ø10 | 4.08 | 4.88 | 6.48 | 8.08 | 2.25 | 2.68 | 3.55 | 4.37 |

| ABR105-R | 10 | CNA | 1 | Ø10 | 4.08 | 4.88 | 6.48 | 8.08 | 2.25 | 2.68 | 3.55 | 4.37 |

*The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions depend on the concrete type, spacing and edge distances.

To obtain the resistance values for a single bracket, the values in the above table should be divided by two, provided that the supported beam is locked in rotation. Please consult our ETA-06/0106 if the beam is free to rotate.

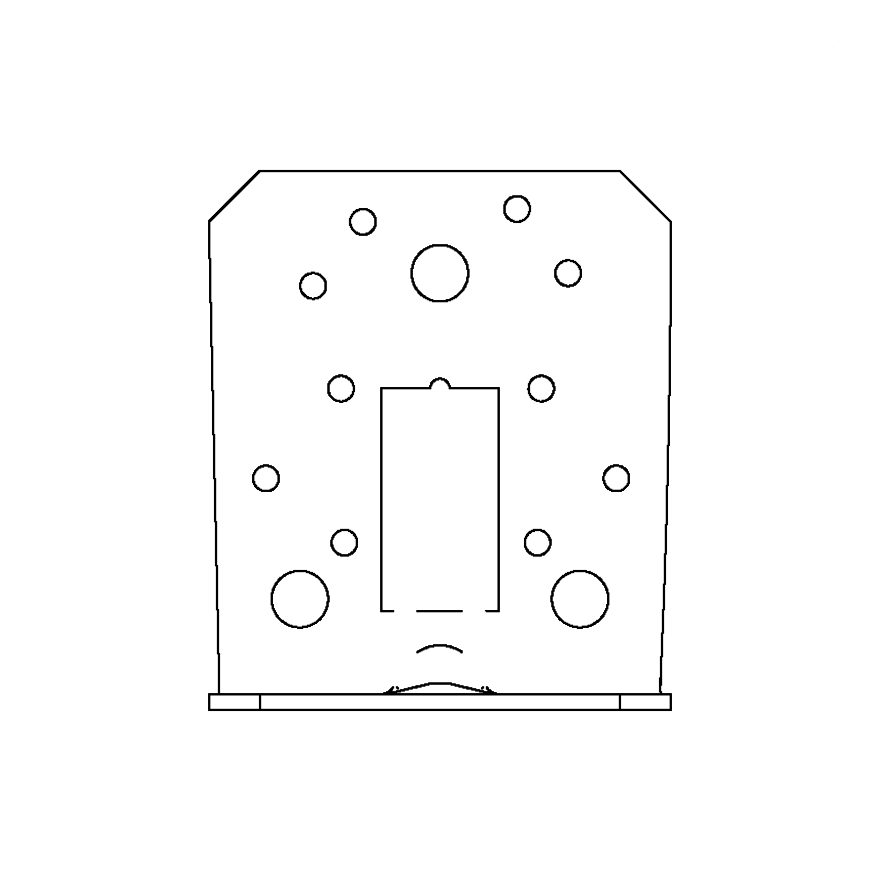

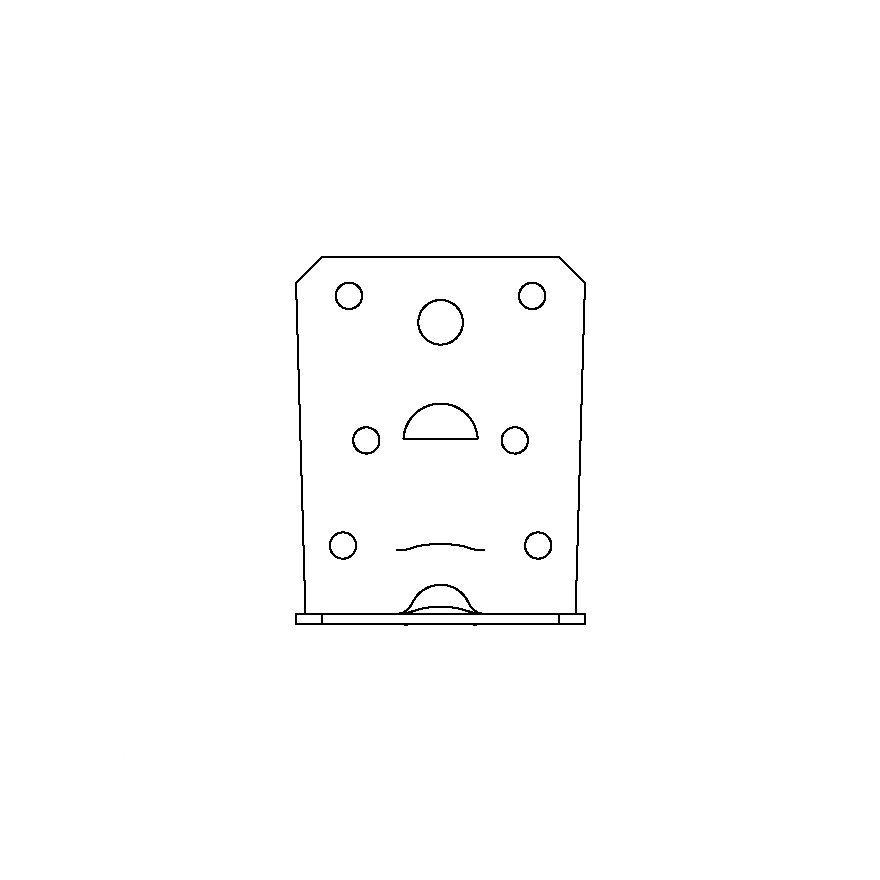

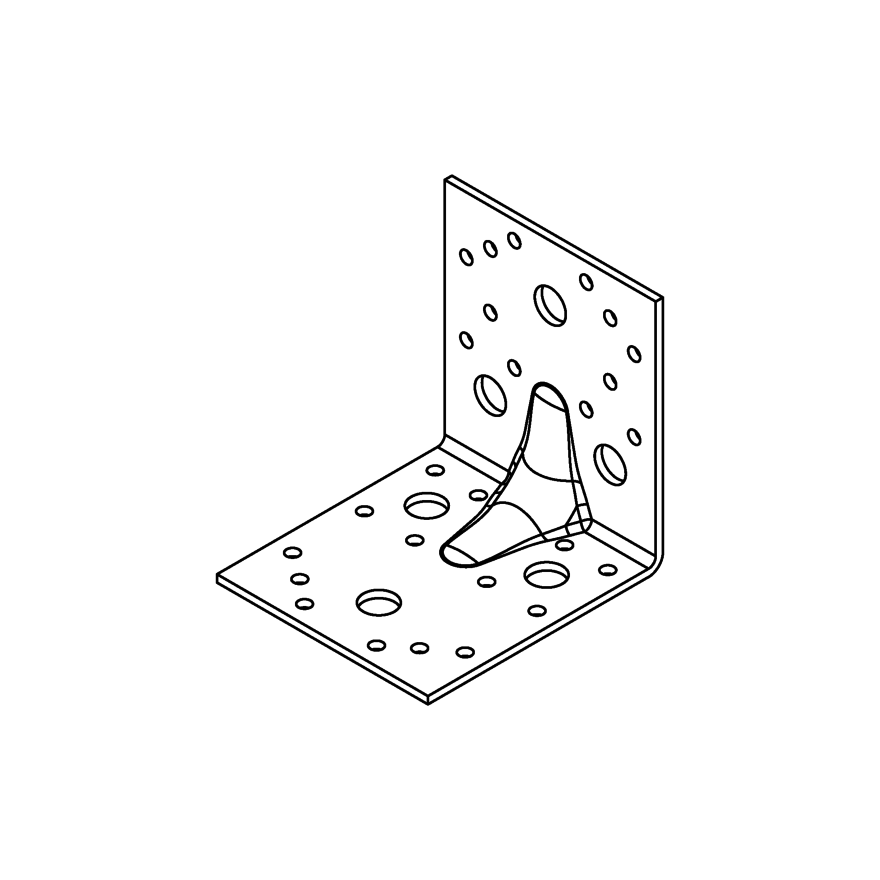

Installation

Installation

Fixing

On wood:

- CNA annular ring-shank nails dia. 4.0 x 35 or dia. 4.0 x 50 mm.

- CSA screws dia. 5.0 x 35 mm or CSA screws dia. 5.0 x 40 mm.

- Bolts.

- LAG screws.

On concrete:

Concrete substrate

- Mechanical anchor: WA M10-78/5 OR WA M12-104/5 pin.

- Chemical anchor: AT-HP resin + LMAS M10-120/25 or LMAS M12-150/35 threaded rod.

Hollow masonry substrate:

- Chemical anchor: AT-HP or POLY-GP resin + LMAS M12-150/35 threaded rod + SH M16-130 screen.

On steel:

- Bolts.